SimPlan simulates high-bay warehouse for REHAU

REHAU AG + Co is an international leader as a premium brand for polymer-based solutions in the construction, automotive and industrial sectors. At the Feuchtwangen site, Rehau invested 25 million euros in a new high-bay warehouse with optimized material flow. After a construction period of 13 months, series operation started at the beginning of the year.

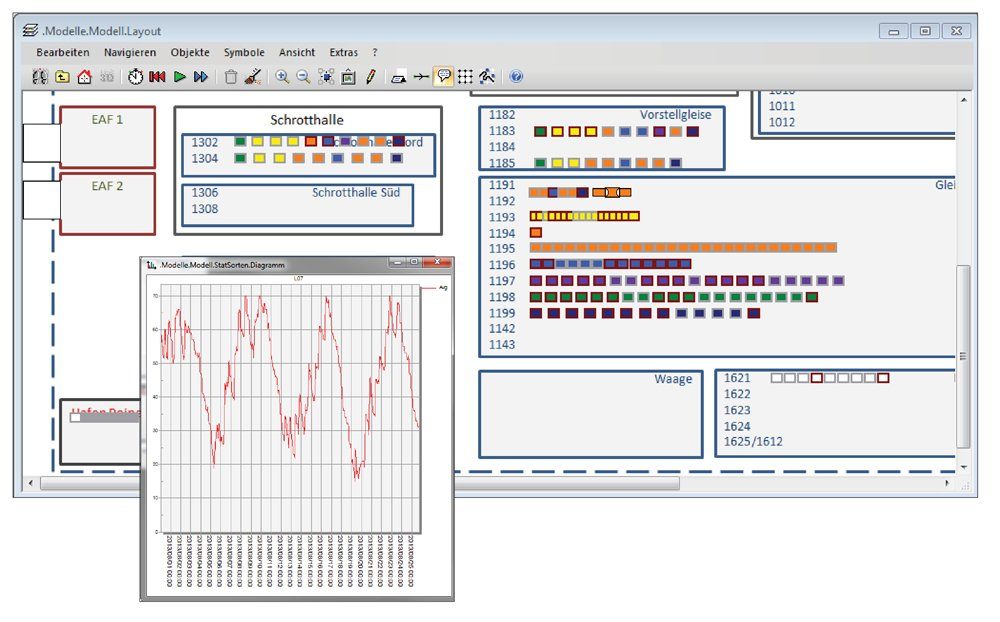

The new material flow system connects the 12-aisle high-bay warehouse with the injection molding, painting and assembly areas. Internal transport is provided by electric monorail trolleys running on a rail system on the ceiling of the plant halls.

The control of the highly dynamic and complex intralogistics system takes into account not only the complete warehouse management, but also the management and scheduling of the electric monorail trolleys and the load carriers.

Parallel to the planning of the material flow concept, SimPlan AG created a simulation model with the aim of validating the system and testing and optimizing the control strategies on the virtual model before implementation.