The connection between simulation and virtual commissioning

Optimal control programs through precise simulation studies

Our simulation studies provide a solid basis for the development of efficient control programs. In special cases, these can even be created largely automatically on the basis of the simulation models, which considerably speeds up and simplifies the programming work.

Increased efficiency through virtual commissioning

During development and after completion of the control programs, virtual commissioning enables comprehensive testing of the functions, independent of the physical system. This method is often referred to as “emulation”, as it exactly mimics the behavior of the sensors, actuators and complete programmable logic controllers (PLCs).

From simulation to emulation: seamless transition

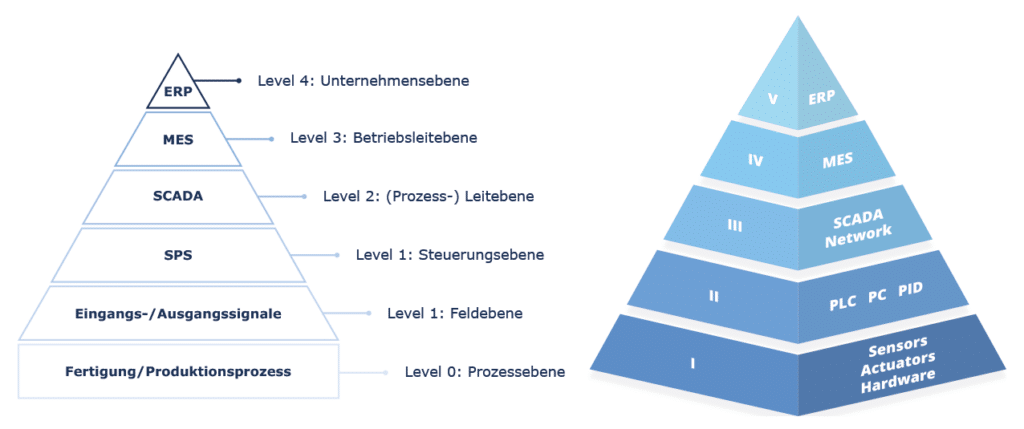

Our simulation models from the system planning phase are the perfect basis for emulation models, structured according to the automation pyramid. This enables a seamless transition between simulation and emulation mode. During emulation, the algorithms integrated in the model are replaced by controls on external systems, such as PLCs or material flow computers (MFR), and synchronized with the model.

Typical areas of application for virtual commissioning

Development of completely new machine and system concepts (prototyping)

As a rule, physical prototypes are used here, which are time-consuming and very costly to produce and modify. In this application, the use of digital twins reduces the number of physical prototypes required and shortens development times, as concepts can be evaluated and improved more efficiently in the virtual world.

Special machinery and plant engineering in general

The classic: Virtual commissioning is used here at both PLC and control level (MES, MFR). The aim is to save costs by avoiding on-site operations; risk minimization, as a mechanical crash, for example, can lead to dramatic delays, but also the careful use of scarce PLC resources.

Retrofits and machine / system expansions

The particular challenge in these cases is that machines and systems are already productive. Conversions and recommissioning should take place within the shortest possible time in order to keep production interruptions as short as possible. Comprehensive virtual pre-tests of the control programs (e.g. based on Emulate3D) are therefore a good way of achieving this goal and keeping the costs of production downtime to a minimum. Virtual tests are also highly recommended in terms of risk management.

Training in a realistic virtual environment

In many industries, there is an enormous shortage of skilled workers, coupled with high staff turnover. This leads to a situation where new employees have to be trained on a regular basis. Digital twins are a good way of achieving this as efficiently as possible. Employees are trained using realistic virtual models and learn how to operate a machine or system in a fun, cost-effective and risk-free way, meaning they are perfectly prepared for the job.

The biggest advantage of virtual commissioning is the time and cost savings

Virtual commissioning not only significantly shortens the start-up process, but also improves the quality of the control systems and minimizes risks through early fault detection. This procedure makes it possible to commission control systems even before the systems physically exist, resulting in numerous advantages:

- Increased machine and system availability through more intensive testing

- Cost savings by shifting commissioning to the office

- Risk minimization through early detection of crash situations

- Adherence to deadlines thanks to parallel testing and other engineering processes

- Possibility to test and optimize changes in the control code before actual commissioning

The exact cost savings achieved through the use of virtual commissioning are often difficult to determine. Errors are identified at an early stage and eliminated before they occur – in the worst case as a mechanical crash. Points such as employee and customer satisfaction are also difficult to evaluate in monetary terms, but are important arguments for the use of virtual commissioning.

Find out more about this topic in our further articles

Virtual commissioning is ideal for automated production and intralogistics systems and is divided into high-level and low-level emulation depending on the requirements. While high-level emulations simulate the entire control system including sensors and actuators, low-level emulations concentrate on sensors and actuators alone.