From manufacture to batch production: Production optimization with a digital twin at RUAG

Initial situation

Challenges during the pandemic

During the coronavirus pandemic, RUAG, a Swiss defense contractor, was faced with significant disruptions to its supply chain. This led to a month-long interruption in the production of the missim Mk3 test device. Once production resumed, it became clear that the manufacturing process, which involved complex manual work steps and long delivery times of up to eight months, no longer met the market’s requirements.

Objective

Conversion to modern batch production

In order to cope with the increasing demand, RUAG decided to switch to batch production. The aim of the “missim 365” project was to produce 365 devices per year instead of the previous five to 15. To achieve this, a ramp-up project was initiated, which started at the end of 2022 and should be completed within a year.

Solution

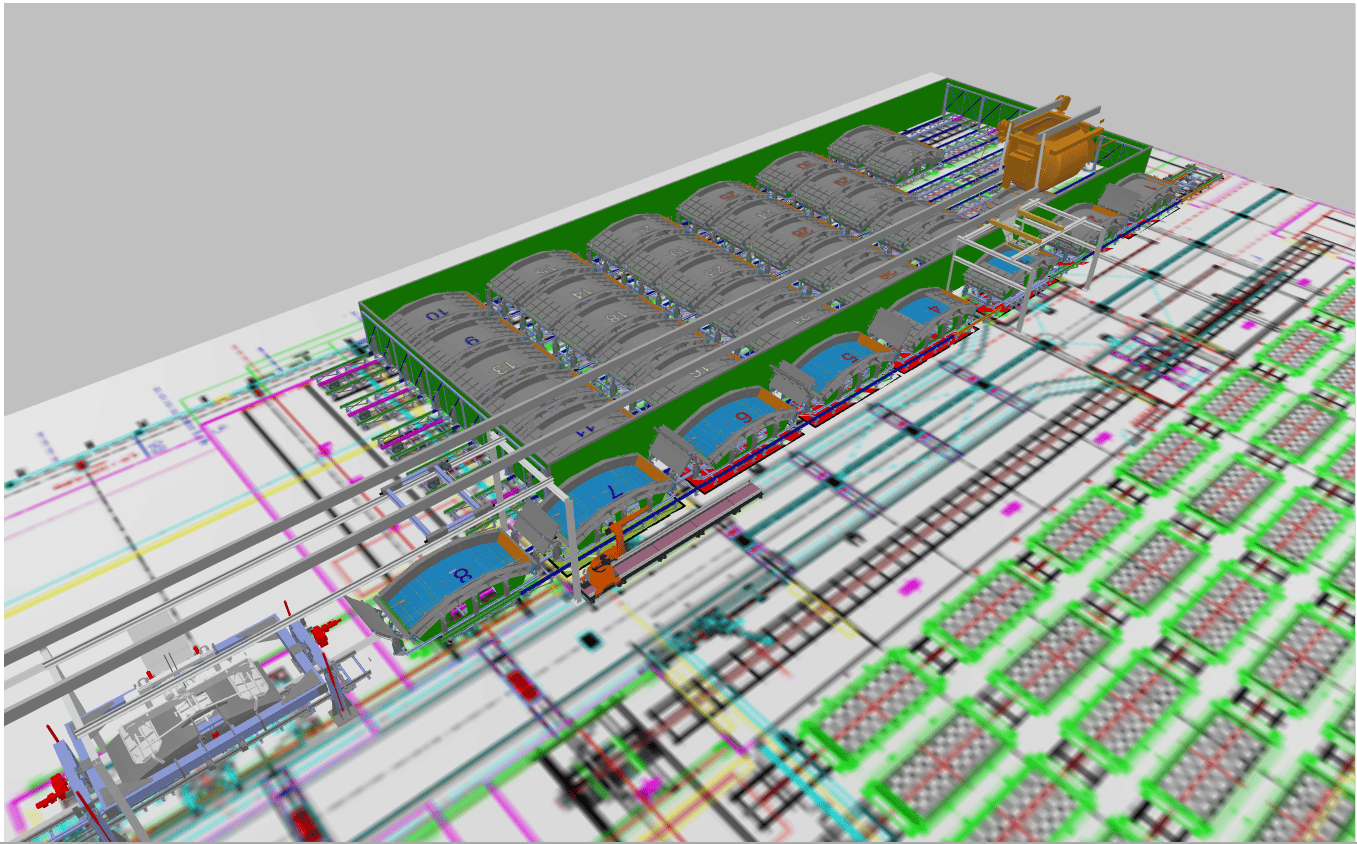

The digital twin as the key to production optimization

The focus of the optimization strategy was the introduction of a digital twin. With the help of the Plant Simulation software from Siemens, the production processes were mapped in a digital model. This made it possible to run through various scenarios and identify potential bottlenecks in production without affecting ongoing operations.

Results

Reduced delivery times and increased production capacity

The switch to batch production led to impressive results: Delivery times were reduced from up to 32 weeks to 10 to 12 weeks. The new production method also enabled a significant increase in production capacity. Up to 365 devices can now be produced annually.

Change Management

Accompanying change according to John P. Kotter

Change management was a key component of the project’s success. RUAG relied on John P. Kotter’s 8-step model to accompany the change. Through regular communication and events, employees were involved in the change process and were able to familiarize themselves with the new work processes.

Conclusion

Simulation as the basis for sustainable production optimization

The introduction of the digital twin proved to be decisive for the success of the production changeover. Bottlenecks were identified and eliminated at an early stage. The simulation will continue to be used in the future as a valuable tool for the continuous improvement of production processes and will contribute to a sustainable increase in efficiency.