Supply chain, value stream mapping and digital twins – trade fair news from the world of simulation

The SimPlan Group, which has been in existence for 30 years this year, will be presenting the latest trends in the fields of simulation and emulation at LogiMat and at Hannover Messe 2022.

With the value stream analysis app SIMVSM, value streams are recorded and processed in a contemporary manner on mobile devices. A comprehensive cloud offering will be added next spring. In the future, users of the app will be able to have their digitally recorded value streams simulated in the cloud. On-time delivery, process capacity utilization, bottleneck analysis, throughputs, warehouse levels and lead times will be clearly visualized over time. The possibility of creating different scenarios and directly comparing the results facilitates the evaluation of the different value stream variants.

With the SimQueue app, SimPlan is expanding its range of easy-to-use analysis tools. SimQueue makes it possible to determine the required buffer sizes for chained lines in seconds. A transfer of the data to simulation models for in-depth analysis is done at the push of a button.

SimPlan will also present the latest features of the AnyLogistix tool from the AnyLogic Group in the area of supply chain simulation. The consideration of CO2 cost data expands the functions for analyzing the CO2 footprint of a supply chain. From improvements to the import/export process to a new help system and user interface enhancements, all the new features can be seen at the SimPlan Group booth.

On display again this year will be a variety of application examples from different sectors and industries. For example, SimPlan will present the benefits and effort of a “digital twin” using the logistics center of the Geberit company in Pfullendorf as an example, and will show how a new production and logistics center with a floor space of 110,000 square meters can be realized without delays in only 15 months with the help of a simulation model using the example of the end customer Häcker Küchen GmbH & Co KG.

With the layouter based on Emulate3D, which was created for the conveyor technology provider Interroll AG, conveyor technology and sorting systems can be individually assembled, calculated and the selection displayed both in 3D and with virtual reality technology.

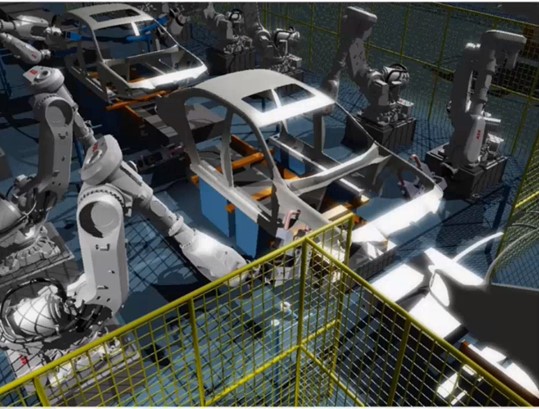

Visitors can also look forward to the latest release of Emulate3D, a software from Rockwell Automation. The Digital Twin software for simulation and emulation has been extended by numerous functions. For example, users now have access to a new communication module for high-level emulation or a completely new palletizing module. A new graphics engine for photo-realistic rendering is also included in the new version.

SimPlan AG

SimPlan AG was founded in 1992 and is today the leading service provider for the simulation of operational processes. SimPlan offers comprehensive simulation services for production and logistics. Customers across industries trust in the services of the “simulators”, including for example companies from the automotive industry, trade and mechanical engineering. From independent consulting on the selection of the right simulation software and IT integration to the professional implementation of simulation projects – SimPlan offers users a full-service package. State-of-the-art simulation technologies are used, above all augmented and virtual reality solutions. The company is headquartered in Hanau. Today, the group includes the subsidiaries SimPlan Integrations and SimPlan Systems as well as branches in Braunschweig, Bremen, Dresden, Holzgerlingen, Munich and Regensburg. The simulation service provider covers international markets with a branch office in Austria and another in China. In total, SimPlan AG employs 120 people worldwide.

Hanover Fair: Hall 5, Booth F48

LogiMat: Hall 8, Booth B04

Contact

Inka Meerwein

Phone: +49 (0)6181-402 96 2503

E-mail: inka.meerwein@SimPlan.de