Simulation is the key to effective factory planning

Planning a factory involves more than just lining up the individual production steps – it means designing a dynamic process in such a way that efficiency, flexibility and future-proofing are harmonised. Simulation is a crucial tool in this process.

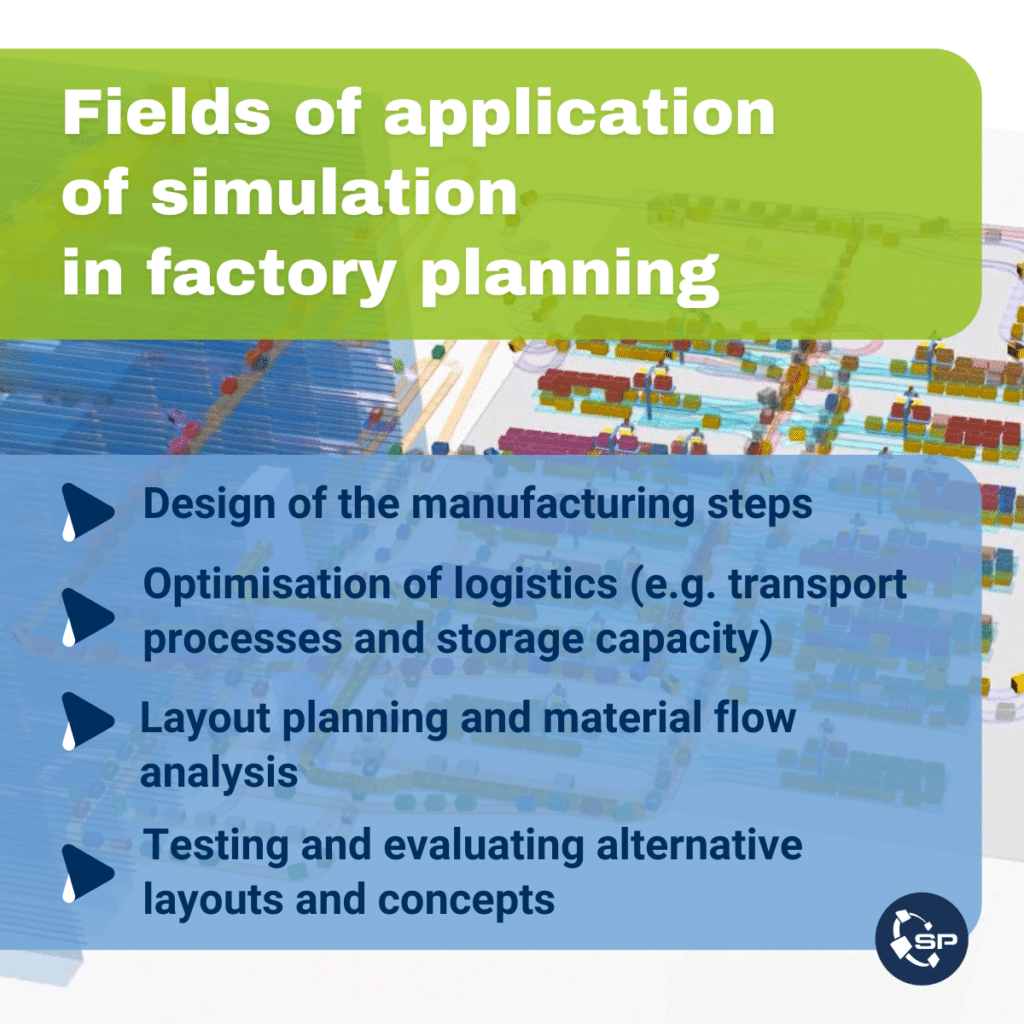

From the design of the production steps to capacity planning, factory planners face questions such as:

- How can production steps for different products be optimally structured?

- Where does production need to be flexibly expandable to respond to future requirements?

- How can a short throughput time be combined with high machine utilisation?

Simulation: the key to flexible and realistic production planning

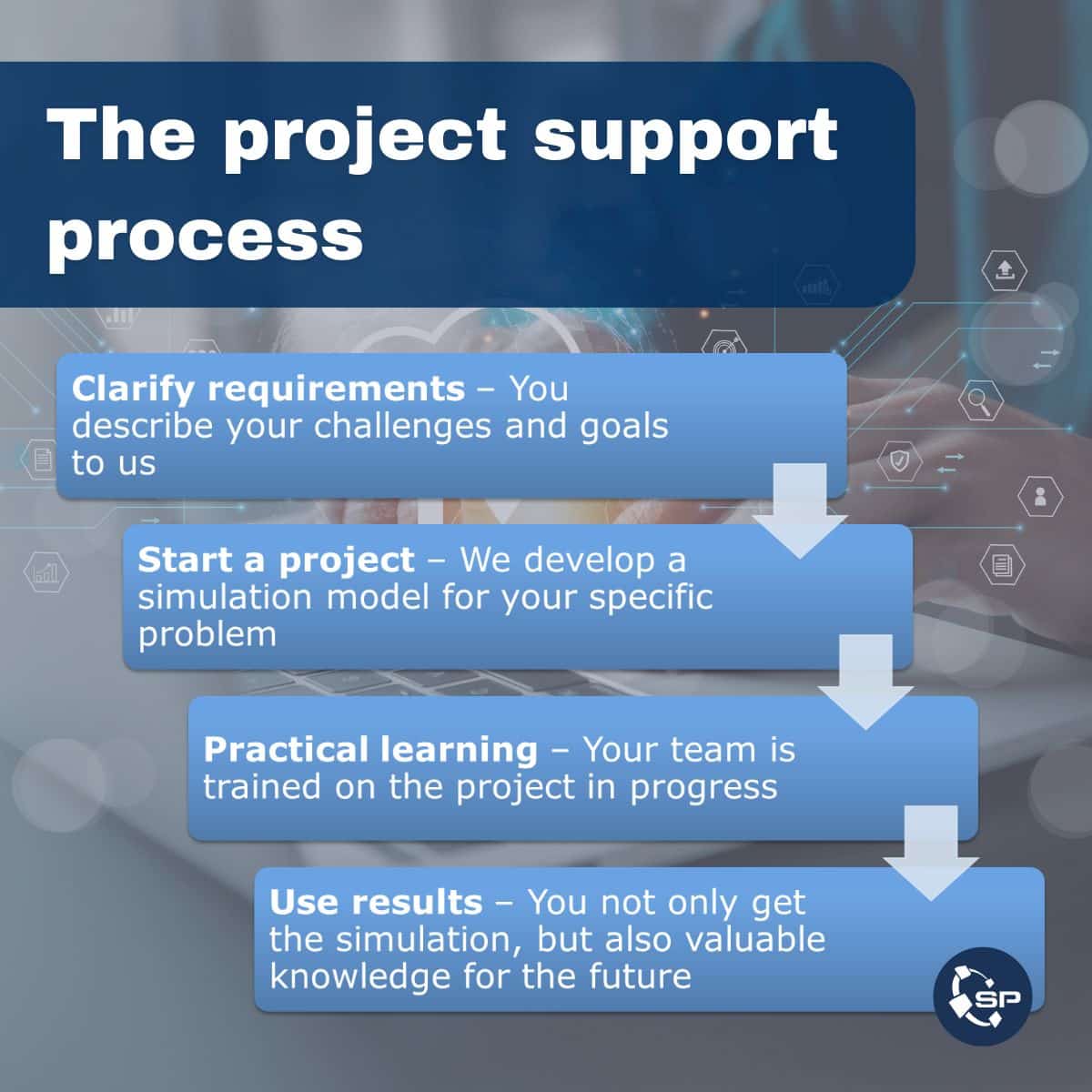

Traditional planning methods can quickly reach their limits when faced with dynamic factors such as varying production content, set-up times, machine availability and quality rework. Simulation offers a solution here: it enables the process to be mapped flexibly and realistically, making the effects of such variables visible.

For example, while static planning only takes into account average values for machine availability, the simulation generates realistic disruption scenarios that show the effects of downtimes of different lengths. The insights gained in this way can prevent bottlenecks that would have serious consequences in reality from being overlooked.

The digital factory also supports the planner in layout planning with the help of simulation. Here, logistics processes, machine arrangement and material flow are tested for their practical suitability, alternative scenarios are compared and the optimal factory layout is derived.

The key to quality and efficiency in planning

Simulation not only provides insights into the planning, but also a reliable basis for effective implementation. Factory processes are optimised in advance and run through in a virtual environment. This helps to avoid errors and the need for rework during operation – a clear advantage for the quality and efficiency of the entire project.

Are you interested in using simulation for your factory planning? Contact us for further insights and practical examples!