Garant – GMO-free production causes complex disposition

Garant pet food GmbH is a market-oriented company that produces compound feed at 3 locations. With 160 employees, Garant generates a turnover volume of about € 90 million. The company can look back on more than 50 years of compound feed tradition. In 1990, “Garant” became the all-Austrian compound feed brand of the warehouses and has since held the market leadership in Austria in the compound feed sector.

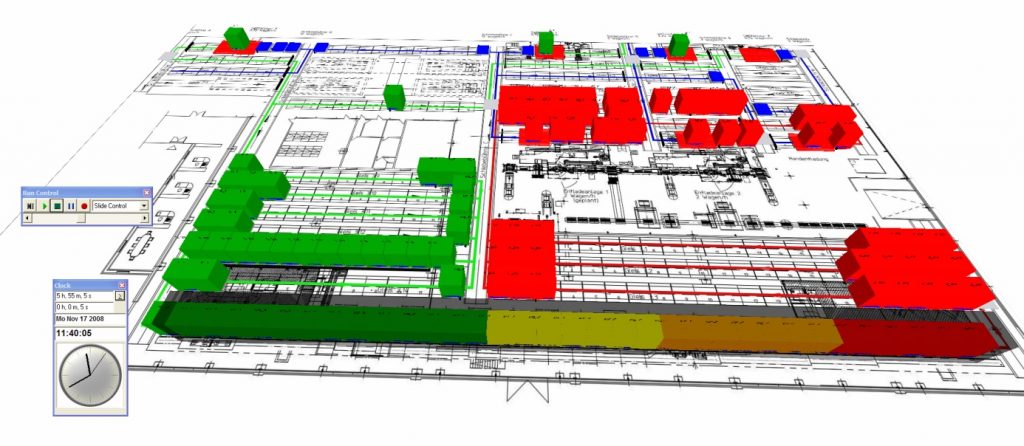

SimPlan Austria modelled the compound feed plant in Graz for Garant pet food GmbH – the Austrian market leader in the compound feed industry – in order to adapt the material flows to the requirements of GMO-free production with the help of simulation. GMOs (genetically modified organisms) and their derivatives may not be used in GMO-free programmes, just like in organic products.

As a result of the worldwide spread and use of GMOs in conventional agriculture and food production, however, there is an increasing risk of undesired contamination of products declared GMO-free with GMO products.

In order to avoid contamination and carry-over, the material flows of GMOs and GMO-free products (OGT – Ohne Gentechnik) must be strictly separated from each other. This circumstance causes numerous dispositive restrictions in production planning and control in compound feed plants when producing animal feed.

Simulation shows influence and impact of restrictions

With the help of computer simulation, the entire compound feed plant in Graz with an annual production capacity of almost 60,000 tonnes has now been modelled at Garant in order to better assess the influences and effects of these restrictions.

Above all, the determination of the limiting capacity as well as the assessment of a concrete investment measure in the area of the finished feed cells were the focus of the expertise carried out by SimPlan Austria.

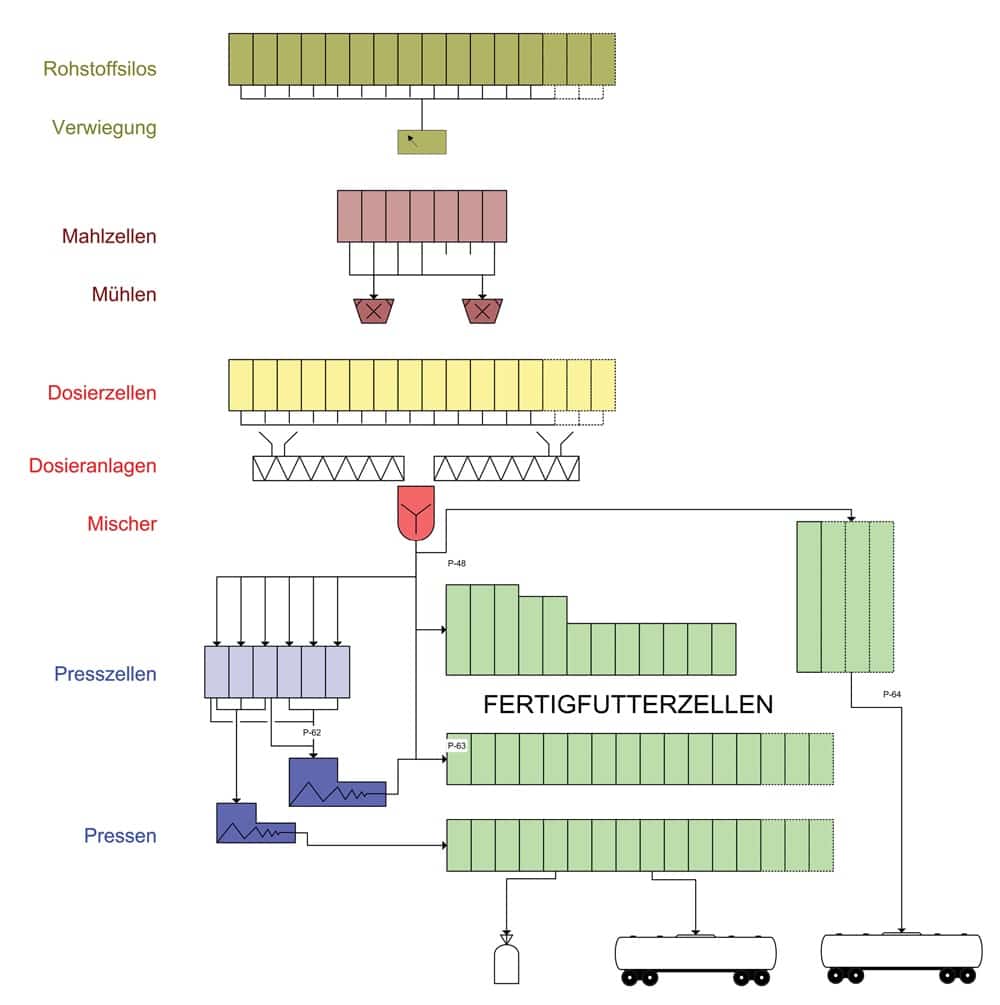

The material bunkered in raw material cells is conveyed via the central weighing system to the grinding cells, where it is made available for the mills. The ground material goes into the dosing cells, from which the quantities are taken according to the recipe and then mixed. Floury products go directly into the finished feed cells after mixing, the remaining products (pressed, expanded, …) are made available to the two presses in pressing cells.

A limiting factor to be taken into account when planning the sequence is that

- not every press is connected to every finishing cell,

- not every press cell is connected to every press,

- the mixer is not connected to every finishing cell,

- not every press can produce every press material, and

- no carry-over of OGT material may occur during a product changeover both in the press cells and in the finished feed cells as well as on the transport route.

In order to comply with all these restrictions, the production manager is repeatedly forced to run so-called flushing batches. In this way, carry-over can be avoided. However, this is bought by expensive set-up times.

Heuristics determine optimal order sequence

In addition to the mapping of the entire material flows, capacities of the silos, filling and conveying systems, the modelling of the control strategies posed a major challenge. The product variety and the strongly fluctuating order quantities also require a wide variety of loading strategies in reality, which had to be implemented accordingly in the model. The dispatched orders are ranked taking into account the carry-over matrix. When forming the sequence, the availability of press cells, presses and finished feed cells must be taken into account in forward-looking planning.

The model created can now be used to optimise the sequence. In doing so, one relies on the use of heuristics, such as genetic algorithms. With the help of the simulation, the use of different heuristics is first examined and evaluated in terms of effectiveness. If the results are as expected, the heuristic found is implemented in a supporting planning tool.