Workflows in the circulation system

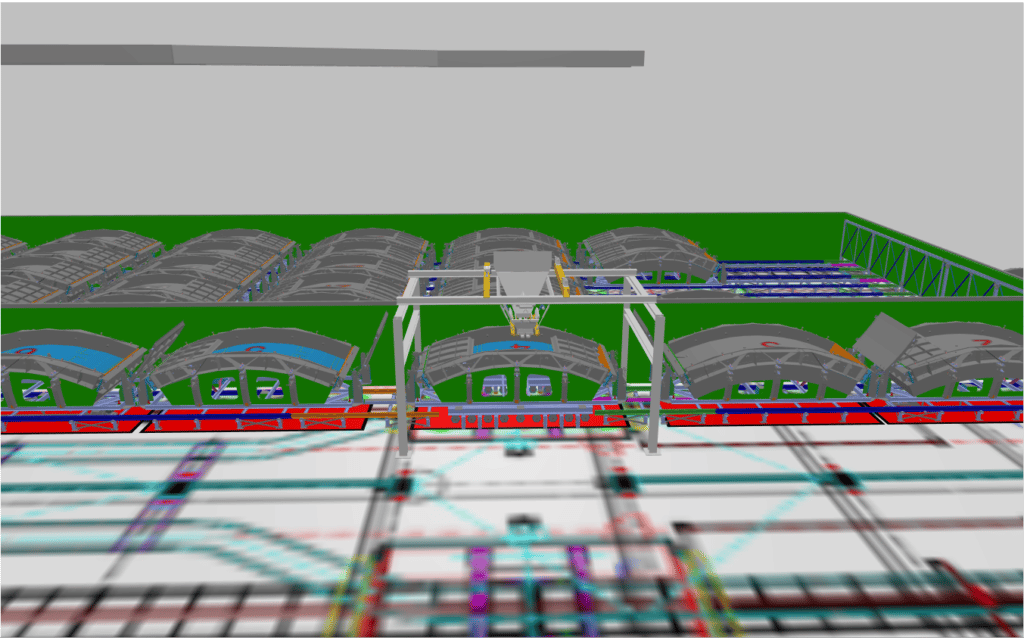

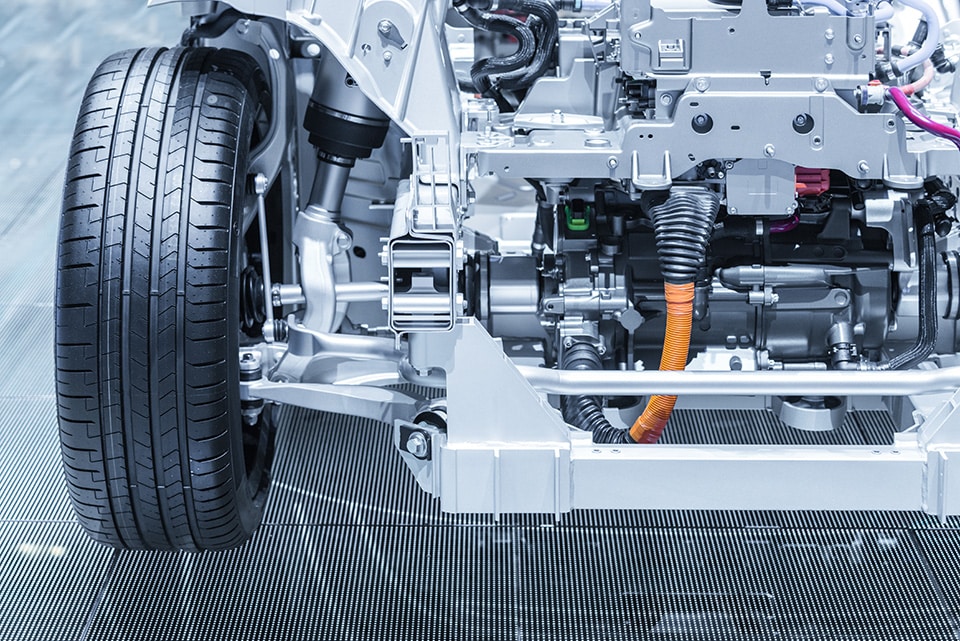

In the circulation system, the formwork passes through a defined production line. There, the following production steps are carried out in a fixed sequence: stripping, cleaning, oiling, inserting reinforcement, closing the formwork, concreting and surface finishing. The formwork moves from one station to the next in a cycle-controlled manner – similar to flow production in the automotive industry.

Once these steps have been completed, the formwork enters a curing oven. The dwell time there depends on the cycle of the circulation system and the number of oven positions available to ensure that the concrete hardens evenly.

Challenges posed by time and process specifications

In addition to the classic requirements for space and automation, additional restrictions had to be taken into account: The entire number of formwork panels had to be filled and transferred to the curing process within one shift. This significantly reduced the available cycle time at the individual stations.

Logistical restrictions due to concrete supply

Another limiting factor was the positioning of the concrete mixing plants, which had to be located away from the filling station for operational reasons. This resulted in longer transport distances for the concrete transport buckets. Each bucket had to make two trips per formwork, which added up to considerable transport times. Braking and acceleration manoeuvres as well as slow cornering further impaired the cycle time.

Automation as a solution

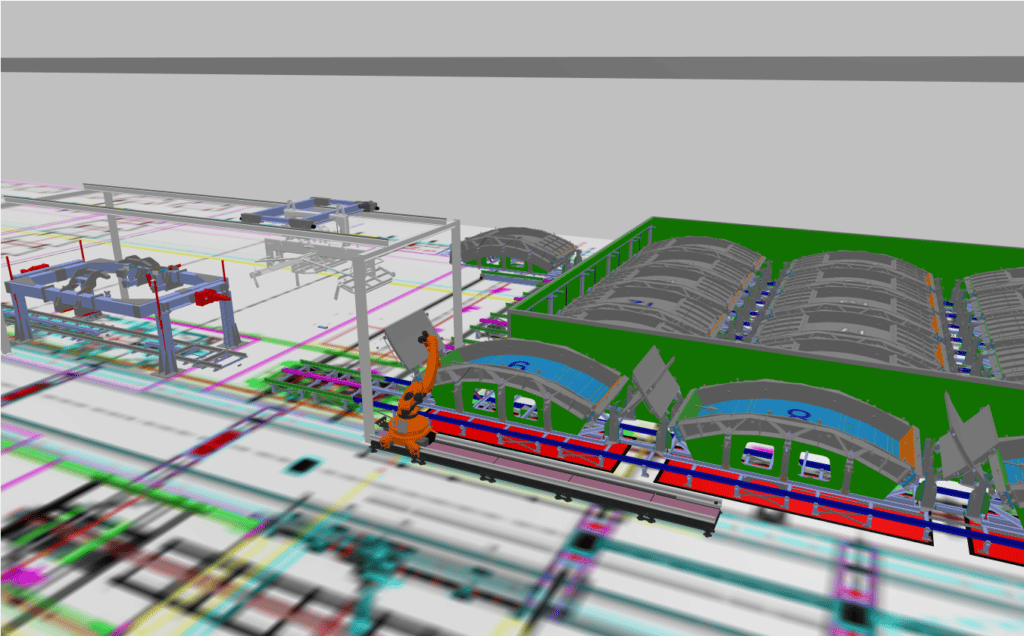

Automation was specifically chosen to reduce personnel requirements. The formwork opens automatically when it reaches the demoulding position. The formwork was to be cleaned by a robot. The closing of the formwork and the surface finish were also planned to be partially or fully automated. Due to production requirements, a second, mirrored circulation system was planned in an adjacent hall. However, this does not affect the cycle time of the first line.

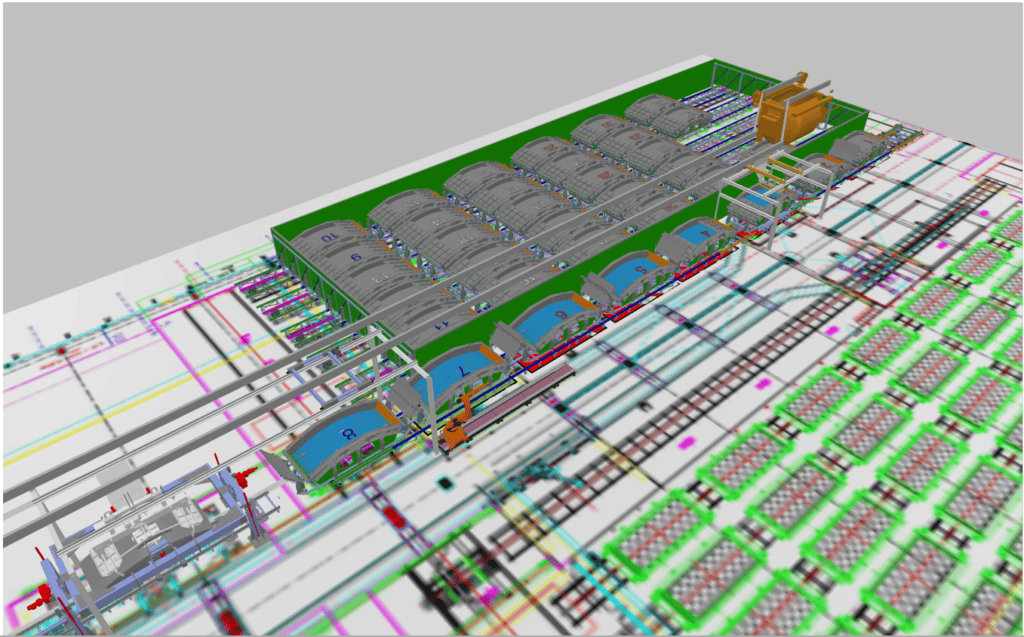

Simulation as a planning tool

Given the large number of process steps and logistical dependencies, manual calculation of cycle times – especially with regard to concrete supply and curing – was no longer practical. SimPlan was therefore commissioned to simulate the entire process. The prerequisite: all machines and systems had to be mapped realistically with their individual motion sequences and speeds.