Simulation of a future plant for the ceramic building materials industry

HANS LINGL ANLAGENBAU & VERFAHRENSTECHNIK GMBH & CO.KG is a leading supplier of machinery and plants for the ceramic building materials industry – from brick and roof tile factories to split tile and stoneware pipe factories to refractory plants.

Task

- Animation of process flows

- Investigation of priority rules

- Support with shift planning

- Capacity planning with regard to the number of kiln cars

- Compliance with technological restrictions

Function

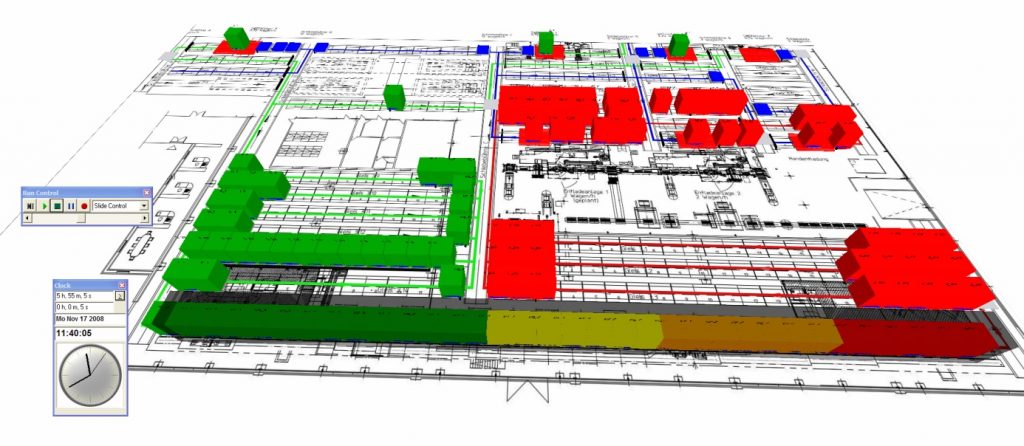

Software: Enterprise Dynamics

- Model parameterisation via a central Excel file

- Layout-accurate representation of the factory building

- Through animation: Process recognition and process understanding

Focus of the simulation

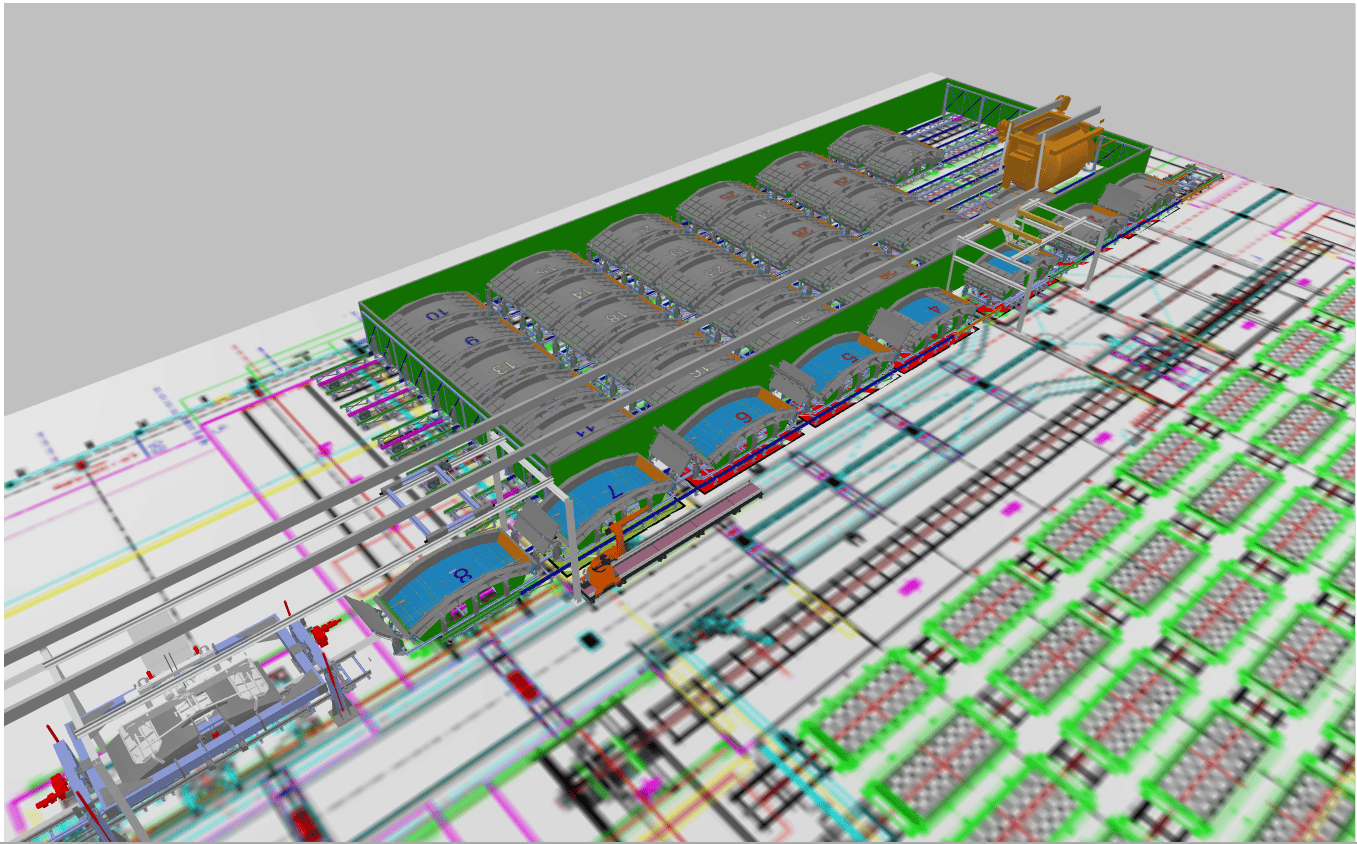

The kiln car circulation system is modelled in a closed loop. The focus is on:

- Priority-controlled transport to and from the kiln

- Compliance with technical and time restrictions

Key questions answered

- How many kiln cars are required to meet all restrictions?

- How many shifts are required and how can they be optimally scheduled?

Results

- Demonstration tool for sales

- Planning tool for capacity and shift planning

- Planning reliability for compliance with technological restrictions