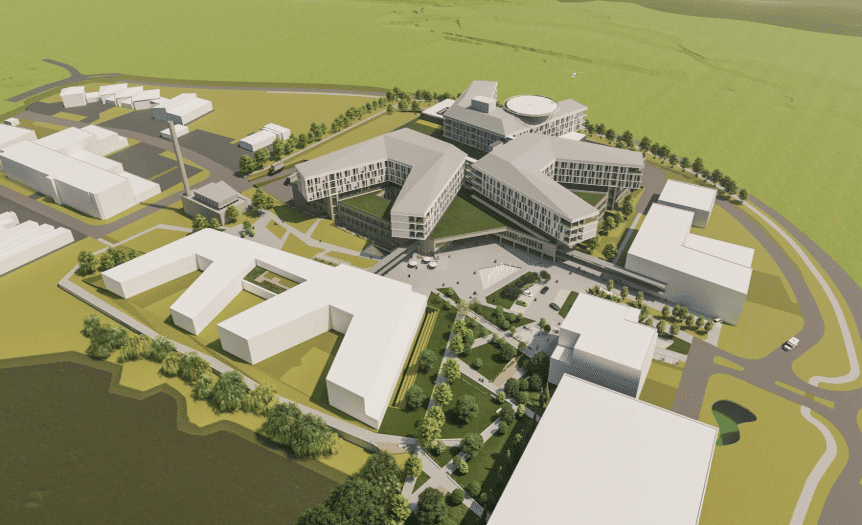

New construction of Central Clinic Lörrach

In 2025, a healthcare campus with inpatient, day-care and outpatient care services will go into operation in Lörrach in Germany’s southernmost southwest. Under the umbrella of the central hospital, the three previous sites of the Lörrach district hospitals and their subsidiary, St. Elisabethen Hospital, will be merged.

The last remaining multiple structures will thus be dismantled and medical competencies bundled in one center, in line with the Hospital Structure Fund and the consistent continuation of the “Lörrach Way”, in the course of which services were already concentrated and medical duplications eliminated between 1994 and 2006. In addition to the central hospital with 685 somatic beds, the campus will also include a center for mental health with 145 psychiatric beds, an interdisciplinary medical center and a health department store.

The complex planning process required diverse and differentiated decisions in order to develop a sustainable hospital concept. The following key topics had to be dealt with fundamentally:

The future range of services:

Which (additional) services are reasonable and necessary for the care of the population of the district in the future?

Will services be discontinued in the future or replaced by newer procedures?

The requirements of the different user groups for the “central hospital” facility:

Which service elements will be demanded by patients in the future, how can the corresponding processes be tailored to the needs of patients?

What measures can be taken to increase employer attractiveness in the highly competitive market for skilled workers?

Financing options and ensuring economic operation:

How are the future treatment and support processes to be designed in order to be able to use spatial, equipment and personnel capacities as effectively as possible and to ensure the economic viability of the operation?

What costs are to be budgeted for and what financing options are available?

Based on the strategic target planning, the consultants from ANDREE CONSULT, Siegburg, drew up a capacity plan that mapped the essential requirements for functional positions, medical-technical equipment and rooms in the space and function program. Based on this, sustainable, differentiated operational concepts were developed for all organizational units of the central hospital and combined in an operational-organizational capacity planning.

Throughout the planning phase, the decision-makers relied on the close involvement of the expertise of their own employees. Thus, regular coordination rounds were initiated by the project manager Thorsten Stolpe. Here, all aspects relevant to the respective discipline were compiled and weighted in order to bring about well-founded decisions within the user steering group. This also ensured realistic planning of future processes and strengthened employee identification with the target project. This is of decisive importance for the success of the project when merging several clinics with different cultural backgrounds. Transparent planning creates trust.

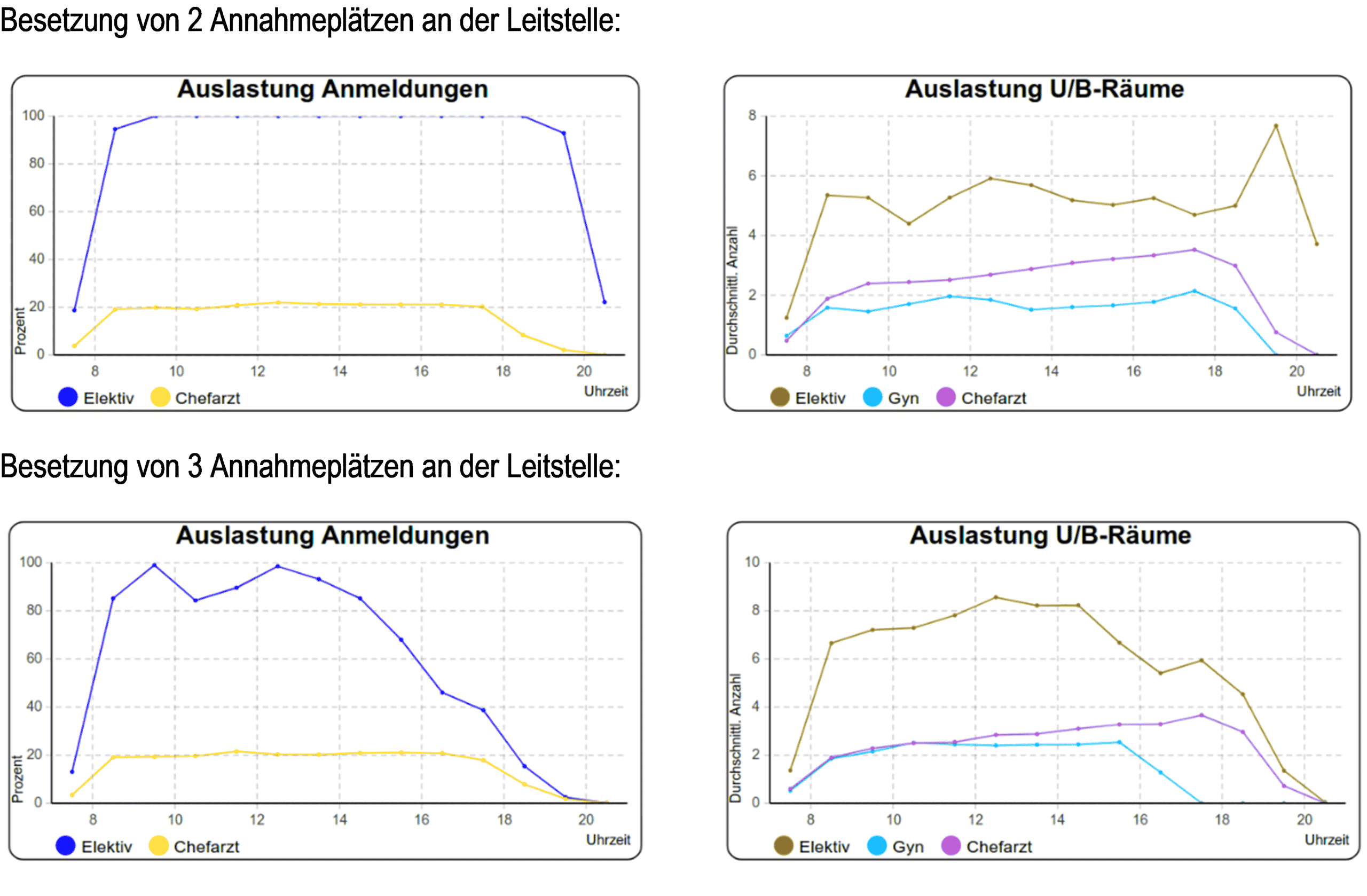

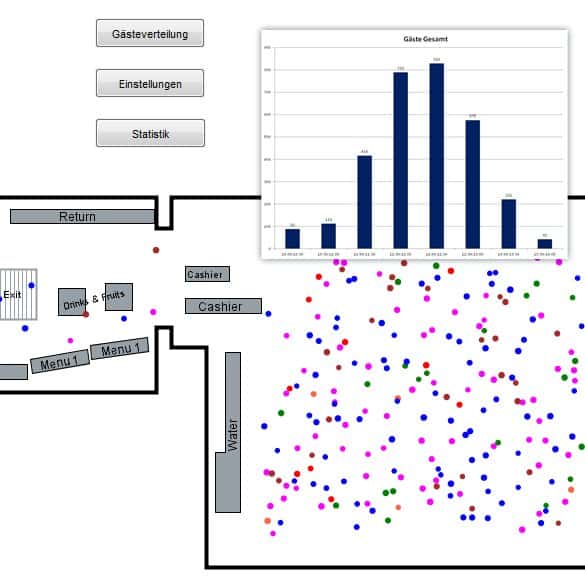

The modern management tool of dynamic simulation was used for the first time in this project to evaluate the space requirements planning. This tool from the service provider SimPlanAG, Hanau, was used for the newly planned functional floor of the central hospital, where outpatient care (emergency care and elective outpatient clinics) will be concentrated in perspective. The simulation software visualized the future processes in the emergency room, respectively in the elective center. The limitations of the (static) calculations made in advance, based purely on average values from the past, were eliminated by the technical simulation. A virtual representation of different scenarios with derivation of the economic consequences is easily possible. In industry, especially in connection with logistical issues, this management tool is already widely used. In the healthcare sector, it is increasingly being used, especially in the context of complete new construction/renovation measures. However, it can also provide valuable support for more complex reorganization projects or for uncovering optimization potential in terms of capacity utilization or routing and help avoid cost-intensive wrong decisions.

A fundamental issue for Zentralklinikum Lörrach was the required room capacities for the central emergency outpatient department and the elective outpatient departments (GKV/PKV), especially since these are areas with a low subsidy share. Based on the operational capacity planning and the underlying calculations, the following parameters were determined:

For Central Emergency Department:

- Number of emergency contacts lying and ambulatory.

- Process times per contact (registration, triage, examination/treatment, advanced diagnosis, advanced examination/treatment, waiting for transfer)

- Medical requirements (requiring monitoring, requiring oxygen).

- Number of rooms available: U-/B-rooms, shock rooms, triage spaces, prone waiting spaces, and registration spaces.

For elective centers:

- Number of contacts for each consultation hour

- Process times per contact (registration, preparation, treatment/examination, follow-up, changeover time, sign-out)

- Special room requirements (e.g., gynecological chair, visit to private outpatient clinic)

- Timing of individual consultations

- Number of available rooms and registration places

In addition, the process chains for both centers (corresponding to the patient path from registration to leaving the building) were defined using workflows that were mapped in the simulation model. Which questions were to be answered as a result of the simulation through corresponding evaluations was defined in advance. In addition to the necessary parameters, the floor plans were also taken over from the planning. This made it very easy for everyone involved to find their way around the visualization. After a short training session, all parameters could be varied in the further course of planning in the user meetings – a simulation with new parameters takes only a few minutes – and thus different scenarios could be analyzed. Cause-effect relationships could be clearly visualized, and the knowledge gained could then be very easily incorporated into the planning process.

As a result, the following information was available to project stakeholders:

Emergency Care:

- U-/B-room utilization, triage spaces, bedside waiting spaces, and registration spaces over the 24h/7d period.

- Patient flows in the direction of further diagnostics, or ward

Elective centers:

- Utilization of the U-/B-rooms and the registration areas in the 12h/5d process (separately for SHI/PKV area)

- Proportion of process times in the 12h course (pre-/post-processing, treatment, waiting).

In order to represent fluctuations in the use of resources as realistically as possible, the simulation took into account not only average values but also minimum and maximum values for the process steps, which were previously defined with the users and then taken into account using random algorithms. In this way, it was also possible to include extraordinary loads such as the simultaneous need for treatment of several urgent and severely injured patients in the calculation.

Simulations as a useful tool for demand calculations in hospital planning

The time and financial effort required to carry out a simulation when determining demand in the hospital planning process is, in principle, very reasonable, even after a critical cost-benefit analysis. Dynamic simulation helps to objectively analyze complex treatment processes and structures. Missing resources or organizational deficits in the treatment process are easy to detect. Due to the possibility of varying each individual parameter, appropriate measures can be implemented easily and their effects can be measured directly.

Leveraging potential not only contributes to business success. Rather, the quality of treatment can also be significantly increased, e.g. through shorter waiting times for patients – which ultimately contributes indirectly to increasing employee satisfaction. Static analysis methods, which are obligatory in hospital planning, cannot provide these insights, or only to a limited extent, because cause and effect relationships are generally not taken into account.

For those responsible for the project in Lörrach, simulation has proven its worth as a decision-making aid. Process flows can be simulated and analyzed virtually – in the inventory without disturbing the respective organizational unit – quickly and with little effort. No special hardware or software requirements are necessary for this. The tool can therefore be integrated into the planning routine in a very straightforward manner. Together with the hospital consulting experts from ANDREE CONSULT and the simulation service providers from SimPlan, it was possible to gain relevant insights into the future space and personnel requirements, and thus ultimately into the financial requirements in the construction and operation of the central hospital, even in the early planning process.

The managing director of the Lörrach district hospitals, Armin Müller, is so convinced of the benefits of the simulation that he would like to see it used in the course of structural hospital planning. Decisions regarding demand planning would thus become evidence-based. For the planning process so far, its use has paid off several times over. The project managers will also use the tool in the further planning process for other issues, such as for the capacity calculation of the AEMP or for the operational organization in the peri-operative unit.

In der Zeitschrift f&w “Krankenhausplanung” Ausgabe 11/2019, ist hierzu ebenfalls ein Artikel erschienen:

Zukünftige Prozesse visualisieren und verstehen

Simulations as a useful tool for demand calculations in hospital planning

The time and financial effort required to conduct a simulation when determining demand in the hospital planning process is generally very reasonable, even after a critical cost-benefit analysis. Dynamic simulation helps to objectively analyze complex treatment processes and structures. Missing resources or organizational deficits in the treatment process are easy to detect. Due to the possibility of varying each individual parameter, appropriate measures can be implemented easily and their effects can be measured directly.

Leveraging potential not only contributes to business success. Rather, the quality of treatment can also be significantly increased, e.g. through shorter waiting times for patients – which ultimately contributes indirectly to increasing employee satisfaction. Static analysis methods, which are obligatory in hospital planning, cannot provide these insights, or only to a limited extent, because cause and effect relationships are generally not taken into account.

For those responsible for the project in Lörrach, simulation has proven its worth as a decision-making aid. Process flows can be simulated and analyzed virtually – in the inventory without disturbing the respective organizational unit – quickly and with little effort. No special hardware or software requirements are necessary for this. The tool can therefore be integrated into the planning routine in a very straightforward manner. Together with the hospital consulting experts from ANDREE CONSULT and the simulation service providers from SimPlan, it was possible to gain relevant insights into the future space and personnel requirements, and thus ultimately into the financial requirements in the construction and operation of the central hospital, even in the early planning process.

The managing director of the Lörrach district hospitals, Armin Müller, is so convinced of the benefits of the simulation that he would like to see it used in the course of structural hospital planning. Decisions regarding demand planning would thus become evidence-based. For the planning process so far, its use has paid off several times over. The project managers will also use the tool in the further planning process for other issues, such as for the capacity calculation of the AEMP or for the operational organization in the peri-operative unit.