Linde optimizes lift mast production at the Aschaffenburg plant with the help of simulation

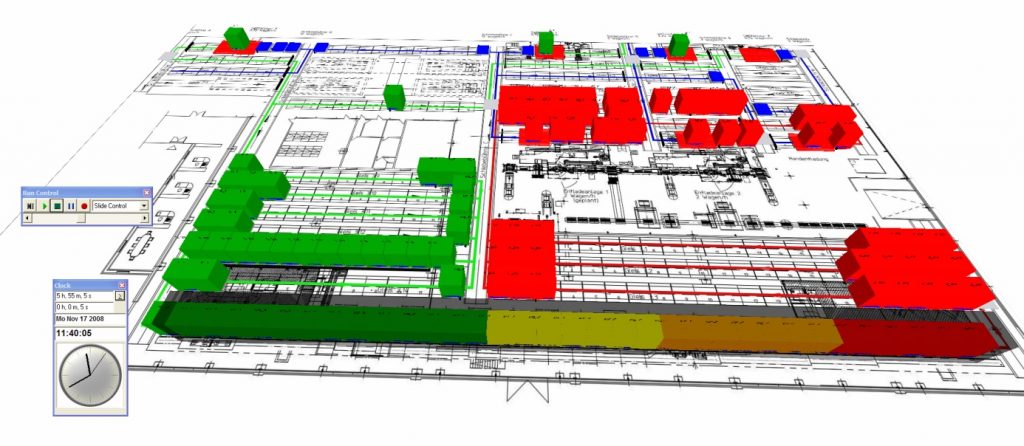

The restructuring of assembly and the introduction of new forklift types confronted Linde with the question of what adjustments could be derived from this for lift mast production. In addition to considering the production capacities, the focus was also on determining the necessary buffer sizes.

Lift mast production classically consists of 3 steps – mechanical production of the individual components, painting of the frame parts and mast assembly. A lifting mast can consist of up to 3 mast frames. In contrast to manufacturing, where the individual components are produced in batches, the related components of a lift mast are processed together in the painting and assembly process. This requires decoupling between mechanical production and the subsequent process steps. The different throughput times of mast production, painting and assembly represent a further decoupling condition.

The simulation model allowed the potential bottlenecks to be quickly identified. The introduction of new automatic welding cells and the fundamental adaptation of job control – to minimize setup times, balance the workload across the lines and optimize job sequencing – led to a significantly reduced buffer requirement in the simulation model in addition to the desired throughput.

A key conclusion from the simulation was the realization that the scheduling of production orders must take into account the capacity restrictions for the individual mast types. Making welding systems more flexible with regard to the types of mast that can be processed also had a very positive effect on the overall process. Ultimately, Linde gained important insights from the simulation study as to which topics they must continue to work on in order to be able to implement production close to the sequence.