Drees & Sommer uses pedestrian simulation to test the feasibility of renovation concepts

Drees & Sommer, a project management and consulting company based in Stuttgart, accompanied the planning of a staff restaurant with the simulation tool AnyLogic, using computer simulation and live tests.

The task: redesigning a staff restaurant

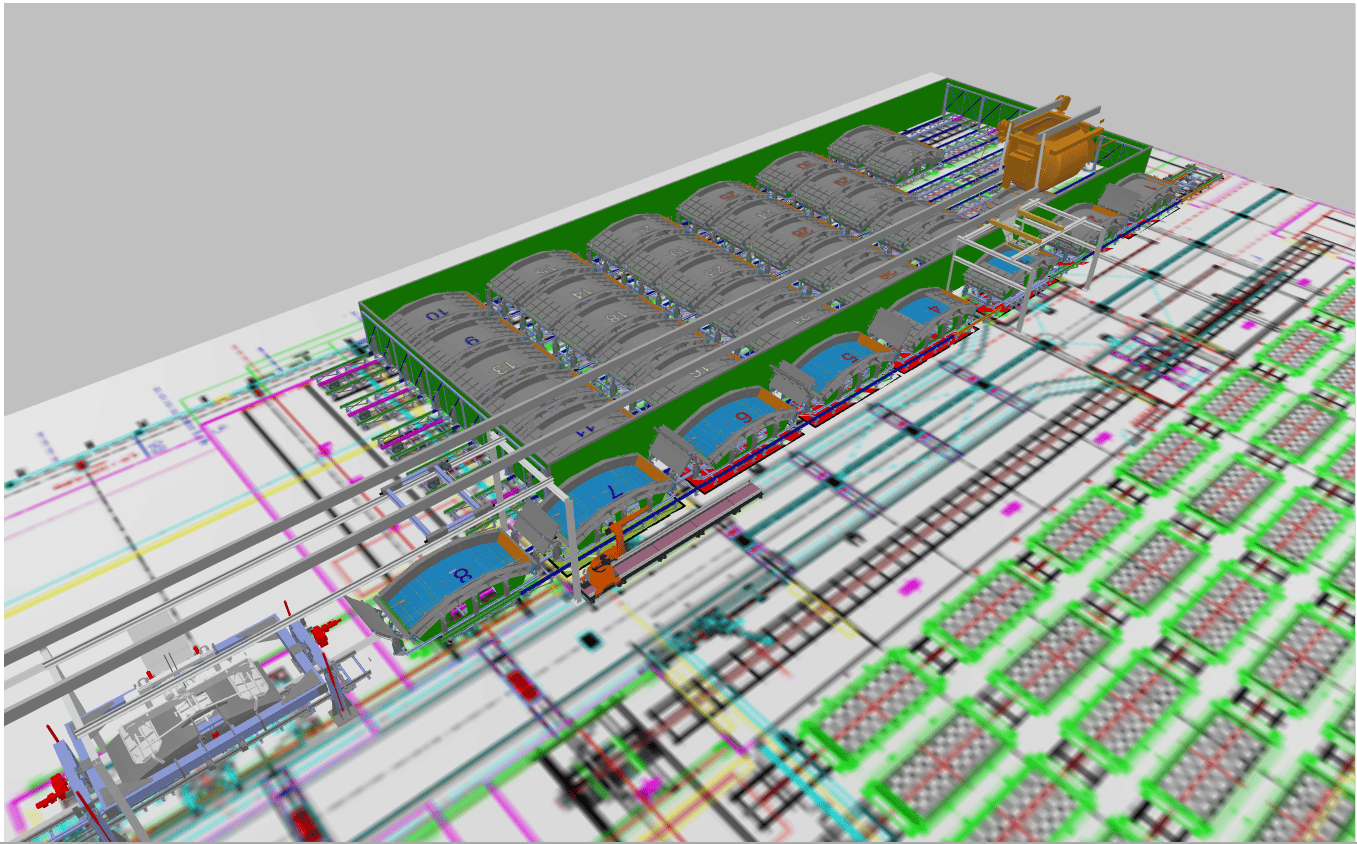

As part of a plant site expansion, an existing staff restaurant currently laid out for 3.000 guests was to be modernised and adapted for larger numbers of customers. Drees & Sommer supported the planning process by simulating, analyzing and optimizing different renovation concepts.

Development of alternatives that accommodate several criteria:

- Avoiding overcapacities and too large areas

- No extensive queues, crowding or bottlenecks

- Sufficient buffets, checkouts and seats

- Logical and easy-to-see pathways

- Planning for possible crisis situations and developing emergency plans

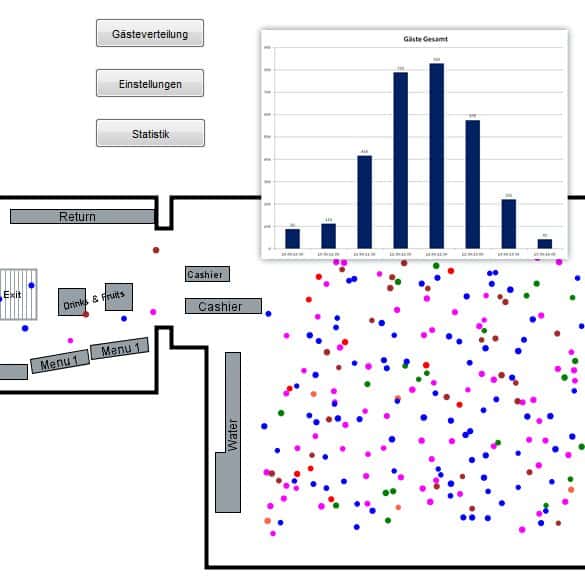

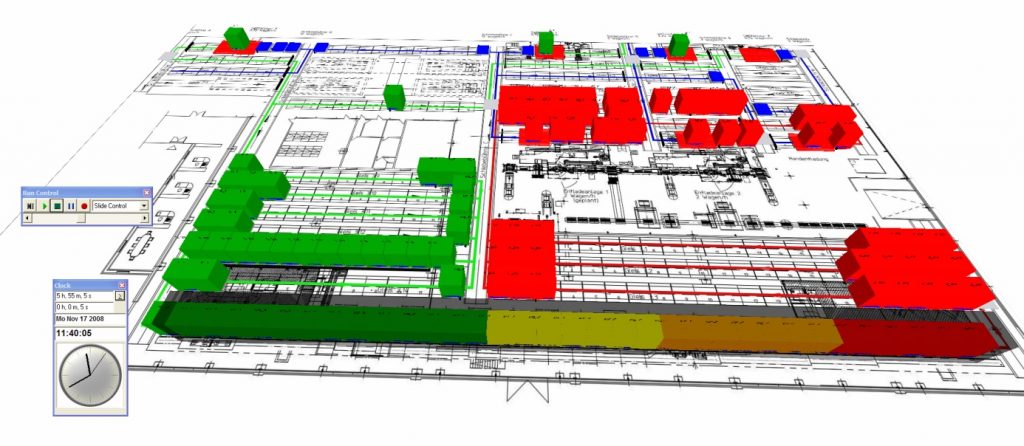

The implementation: agents promote understanding

With the help of pedestrian simulation, the behavior of thousands of guests was modelled, analysed and influenced dynamically in different planning scenarios. Every one of the simulated guests (called “agents”) adheres to predefined parameters and, like real people, finds its way through the building.

This way, the different simulation alternatives can be compared quickly and easily. The effects of changes in service times, the number of service points and the layout of pathways become immediately apparent. For example, if the number of arriving guests exceeds the cycle times of the service points, queues form and indicate that planning needs to be optimized for this area.

Drees & Sommer used this as a first step to reduce the number of planning alternatives.

Added reliability with live tests

The remaining alternatives where tested by replicating the simulation results in live tests. Here, the future floor plans and room layouts were imitated and around 35 people re-enacted the bottlenecks of each scenario. This improves the evaluation of people density, space utilization and customer well-being.

Additionally, Drees & Sommer was able to develop and implement improvements directly on-site and document their effects with videos and photos. The following analysis and summary of the improvements made it possible to justify decisions transparently and reliably.

Reduction of risks – benefit for the customer

With the results from pedestrian simulation, well-founded decisions for or against a renovation concept for the staff restaurant could be made. The risk of possible mistakes or unrealised improvements was minimized through the simulation. The efficient use of the available space and a high degree of customer well-being in the restaurant mean a benefit for the guests that more than offsets the one-time costs for the pedestrian simulation.

Minimal effort and costs

For the client, the additional costs of the simulation study were minimal and results were always presented on time.

The following milestones ensued for the client:

- Client workshop to determine project basics

- Creating and evaluating the simulations

- Presentation of results and selection of the usable alternatives

- Live test of critical situations and final adjustments to planning

- Decision for the optimal alternative

The result was an optimized planning alternative, which allows a smooth pedestrian flow and avoids long waiting times. Future bottlenecks were recognized and eliminated, space utilization was improved and customer flow in the staff restaurant optimized.

The simulation model

Take a look at the real model at runthemodel.com (opens in new tab, Java needed):

_