Singapore Aero Engine Services (SAESL) plans the future

SAESL is the world’s largest service provider for the maintenance, overhaul and repair of Rolls-Royce aircraft engines, so-called Trent engines. Currently, the company has the capacity to handle over 300 Trent engines per year. In 2019, SAESL launched a capacity planning project for the next 10 years, during which SAESL expects a significant increase in the number of engines to be processed.

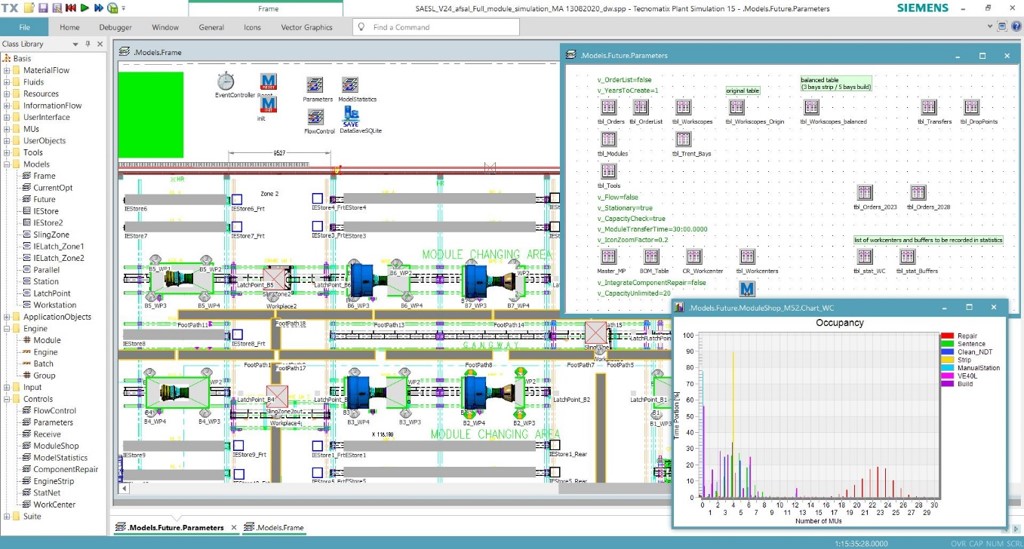

With the help of the simulation the following questions should be answered:

- Up to which year can SAESL still manage with the existing production capacity? Where are the current bottlenecks in the process and what measures can SAESL take to increase capacity?

- Is the planned manufacturing concept suitable for handling the future order volume? How many engine machining stations are required? What investments are required in the module repair area?

SAESL commissioned SimPlan to set up a suitable simulation model, to conduct a simulation study to answer the questions posed, and to train SAESL employees to use the simulation independently within the company.

The simulation was to generate a realistic order volume for the future based on forecasts. This program had to take into account a suitable distribution of engine types on the one hand and a conservative estimate of the repairs to be handled on the other. Another challenge was to map the type-dependent process times for the individual engine disassembly and assembly steps as well as the dynamic allocation of personnel and tools.

In module repair, we started with an initially rough mapping that simulated the fluctuating process times of the individual modules based on the engine and machining type (testing only, individual repairs, or full engine overhaul). We were able to take the required parameters from the diagrams in the value stream mapping. However, it quickly became clear that these parameters were not detailed enough for the simulation. In direct discussions with the production staff, we refined the data and transferred it to the model.

After several optimization loops and many experiments based on various assumptions about future volume and type distribution, we were able to provide SAESL with a forecast by when and with the implementation of which improvement measures the current production capacity will be sufficient. In addition, we were able to test and optimize the future concept. In doing so, we were able to show savings of up to 30% with regard to the necessary investments in technical equipment. Thus, the effort for the detailed simulation of the process including the revised and refined process parameters paid off several times.

SimPlan continues to support SAESL in answering various questions in the application of simulation. Currently, a closer connection of the SAESL value stream mapping with the simulation based on SimVSM is being discussed.