What actually is a simulation?

On the following pages we would like to give you an initial insight into the world of simulation.

Here you can find the answers to the following frequently asked questions:

On the following pages we would like to give you an initial insight into the world of simulation.

Here you can find the answers to the following frequently asked questions:

Simulation is the digital replication of a dynamic system using a model that is used for experiments to gain real insights. In process simulation (DES), processes such as material flow or logistics are simulated to create transparency, minimise risks and implement optimisations throughout the entire life cycle.

Simulation is the representation of a system with its dynamic processes in an experimental model in order to gain insights that can be transferred to reality.

In simple terms, this means:

In practice – especially at SimPlan – we use process simulation, often referred to as discrete event simulation (DES). This involves modelling processes in which piece goods or other objects flow through defined sequences with fixed time specifications, for example through production lines or warehouse systems.

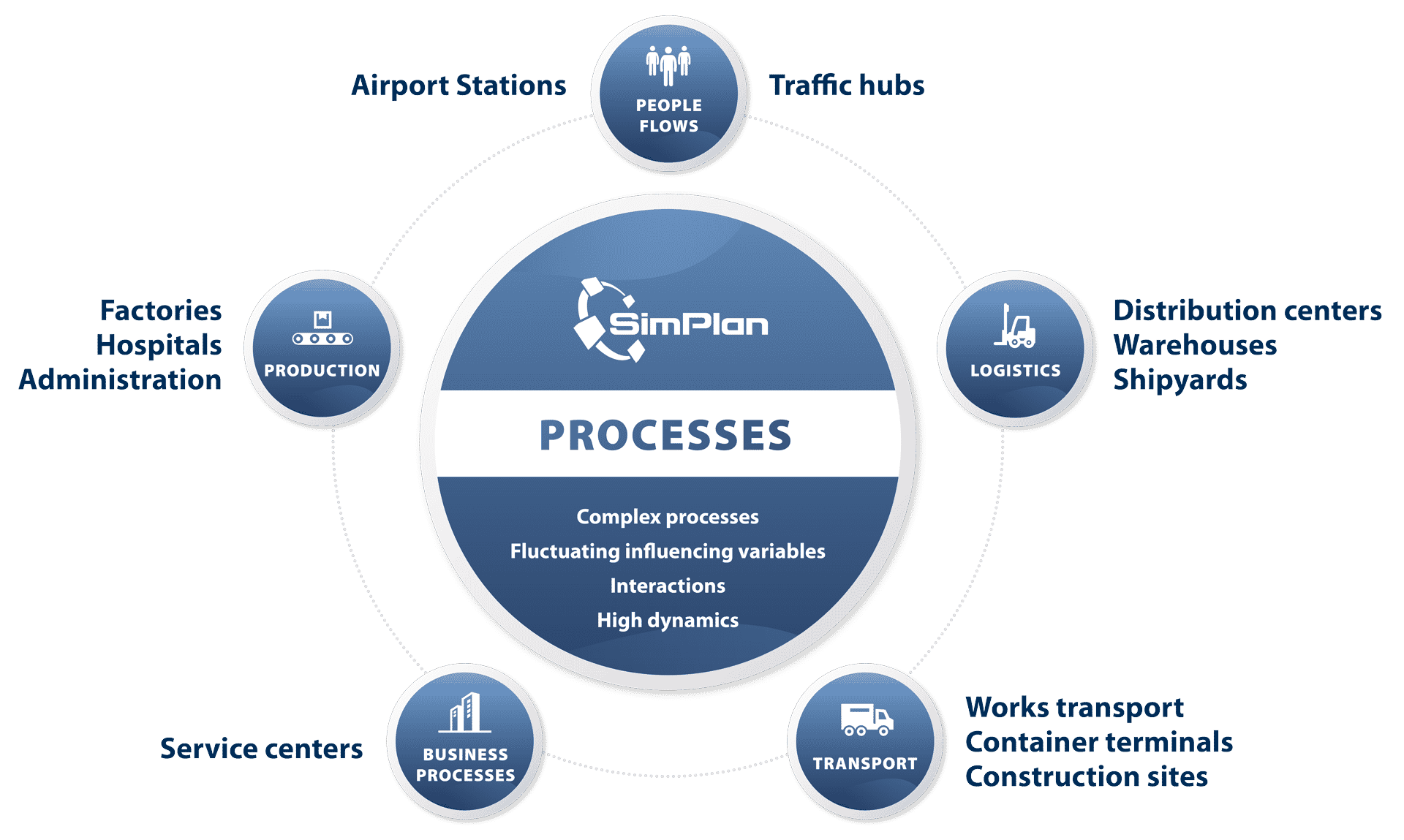

Traditionally used in areas such as:

However, this method can also be successfully extended to simulations of people flows, business processes, transport networks or supply systems.

In sales and marketing, simulation is primarily used to clearly visualise planned systems and processes. It creates transparency, facilitates decision-making and strengthens the confidence of potential customers – in special cases, also through detailed simulations with key figures.

In addition, modern research shows that simulation in marketing and sales is also used for sales forecast modelling, campaign planning and price scenario analysis. Simulations help to run through different strategies virtually – for example, to optimise prices or advertising channels. This enables data-driven decisions to be made and resources to be used efficiently.

Simulation supports the evaluation of new plants and the optimisation of existing systems. It saves time and money by allowing scenarios to be tested without risk. Modern approaches such as Plant Planning 4.0 or the combination with scheduling and optimisation make it a flexible planning tool.

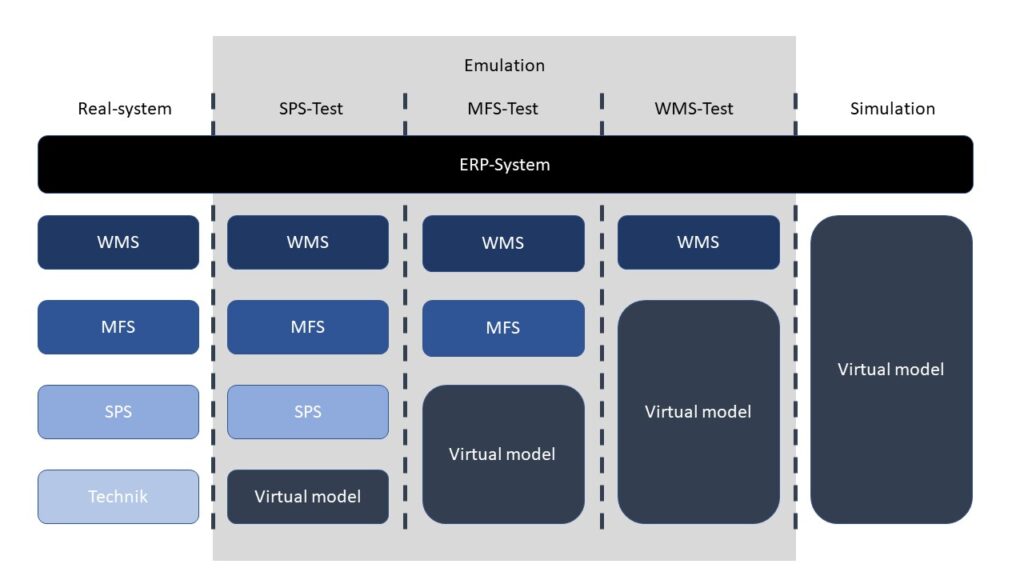

During the implementation phase, simulation enables the virtual commissioning of control systems. Programmes can be tested independently of the actual plant, errors can be detected at an early stage, and commissioning times can be shortened, right through to real-time testing with hardware-in-the-loop.

During the implementation phase, simulation models provide valuable results for programming the control system. In special cases, the control code can even be generated automatically from the model to a large extent.

Virtual commissioning allows control software to be tested independently of the real plant. Sensors, actuators or entire PLCs are emulated by the model or linked to it. Appropriately structured models allow easy switching between simulation and emulation mode.

Yes: Simulation can be used as a forecasting tool (digital twin) for day-to-day operations or as an operator model for future adjustments. This allows processes to be secured, scenarios to be compared and changes to be implemented quickly and without risk.

Simulation can be used as a predictive tool during ongoing operations. Testing the daily schedule shows at an early stage how orders, batch sizes or machine utilisation affect throughput times, personnel requirements and plant utilisation. This allows scenarios to be played through and the best processes to be selected before production starts.

In order for a model to be used as a digital twin, it must be linked to real data. This includes, for example, current order statuses, cycle times, setup times and availability. The more complete these parameters are, the more accurate the forecasts will be. In some cases, the simulation results are additionally supported by optimisation methods such as heuristics.

Even after the project has been completed, a simulation model can be used in the long term. Operators use it to check future adjustments – for example, the integration of new products or logistics handling for new customers.

The advantage lies in the speed of implementation: since the actual model already exists, it only needs to be adapted to the planned changes. This saves time, facilitates decision-making and reduces risks.

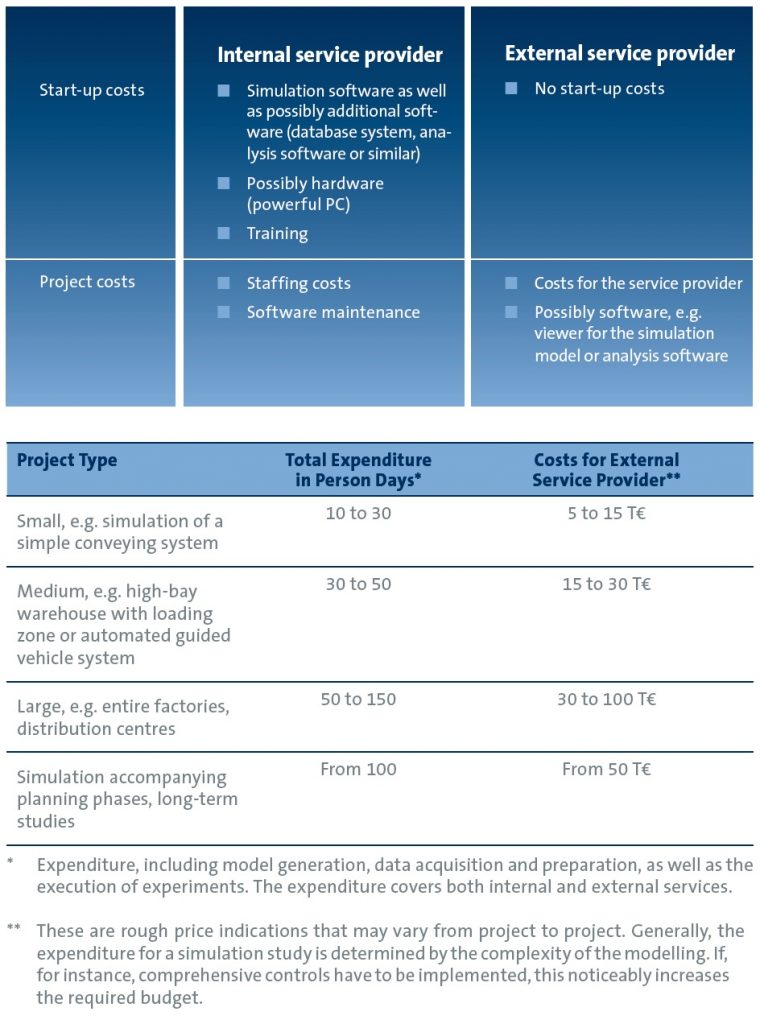

Before the decision for or against a simulation study is made, it should be clarified whether all conditions for a successful project have been fulfilled. If there is a lack of experience with the simulation tool, it is recommended to call in a consultant already during the initial decisions. He will be able to judge whether simulation is suitable for the specific problem.

During the initial phase you should also decide whether:

This decision should be made based on the following conditions:

Example for a plant visualisation with Demo3D – source: Kuka Systems GmbH

Furthermore it must be noted that a lack of experience with handling simulation significantly

In order to avoid this, an experienced consultant should ideally support the first project, even if internal resources are being set up. This guarantees an effective transfer of know-how to the newcomer.

However, other alternatives, such as the ‘external workbench’ are also possible. This means that an internal employee is trained in the execution of simulation projects and in the operation of the models, while the models themselves are created by an external service provider.

After the decision to carry out a simulation study has been made, the question of the right simulation system or the appropriate external service provider arises.

When purchasing a simulation system, several factors must be taken into account, for instance:

Most simulation system vendors offer a trial installation or let customers rent their system for a limited period of time. These offers are particularly useful as it is only by handling the software that you get to know its’ advantages and disadvantages and will be able to effectively determine the appropriate system for your individual requirements.

Alternatively, you may decide to use our tool laboratory. Within one or two days (depending on the scope of the task and the number of simulation systems to be tested) you can test established systems based on your individual project requirements.

This will provide you with a solid overview of the range of features and the user-friendliness of the different software systems. Today a constantly increasing number of consultancies offer simulation services.

The following table shows the basic classification of simulation projects and the expected costs.

Simulation pays off economically: studies show an average ratio of 1:6. In addition to direct cost savings, it creates transparency, reduces risks and speeds up commissioning.

The specific monetary advantage cannot be determined precisely in advance. Studies and benchmarks (e.g. VDI) estimate the average cost-benefit ratio to be around 1:6 – meaning that every pound invested in simulation yields a multiple return. For large investments, such as in car body construction in the automotive industry, the ratio is often even more favourable.

However, there are also projects in which simulation primarily serves to validate plans without identifying additional optimisation potential. Even in such cases, simulation creates transparency and reduces risks.

The following questions should be used to decide whether simulation is appropriate:

In addition to pure cost advantages, simulation also offers qualitative benefits – such as shorter commissioning times, faster start-up of systems and a significant reduction in investment risk.

The success of a simulation project depends on clear objectives, good data quality, the right team composition and the early integration of simulation into the planning process.

Simulation only proves its worth if a number of key factors are taken into account:

Successful process simulation requires clear objectives, appropriate data, an interdisciplinary team, a budget and suitable software. Equally important are openness to results and a willingness to draw conclusions from the simulations.

Precise and complete data on processes, resources and structures are essential for a successful simulation. The better the data quality, the more realistic and meaningful the results.

The quality of a simulation stands and falls with the available input data.

Missing or uncertain data can sometimes be supplemented with assumptions or empirical values. It is important to make these uncertainties transparent and to take them into account in the model using sensitivity or scenario analyses.

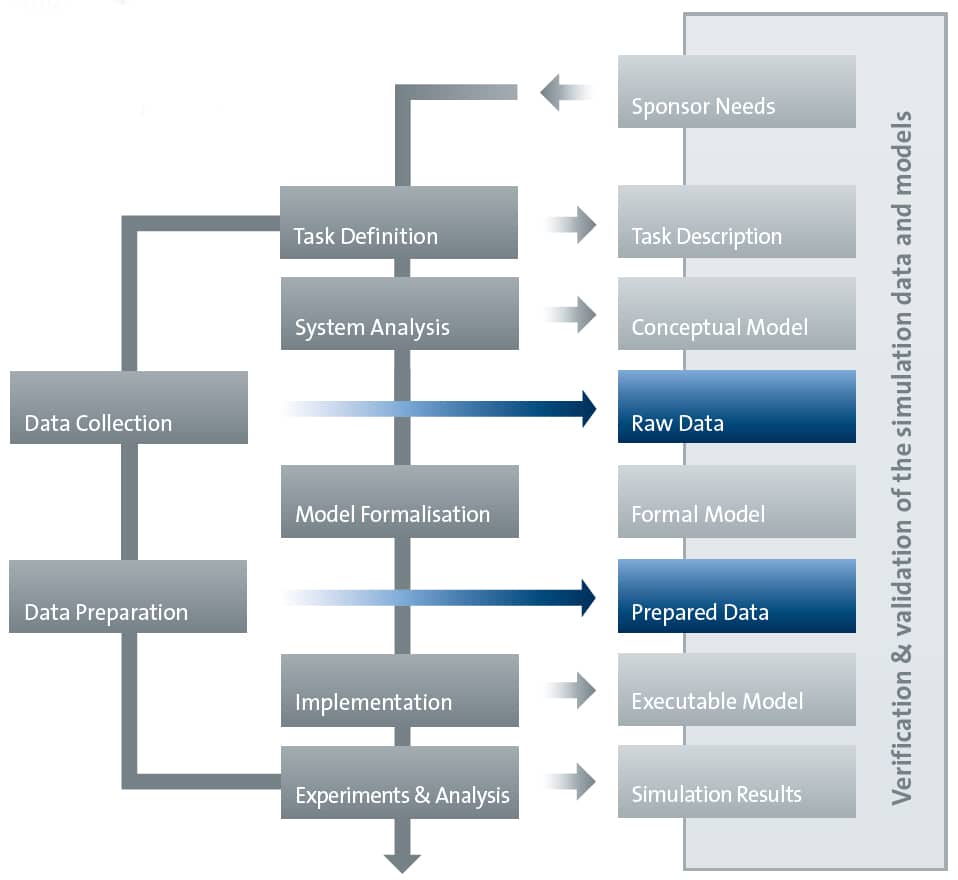

A simulation project follows clear steps: from defining objectives and data acquisition to modelling and implementation to analysis, verification and validation. This produces reliable results for informed decisions.

At the beginning, the project objectives are defined and the task is described precisely. A clear question is crucial for the later use of the simulation.

The system to be examined is analysed and the relevant data is collected. This includes, for example, process times, capacities, layouts or control rules.

The raw data obtained is structured and prepared before being transferred to the simulation model. The model is then formalised in order to realistically map the processes.

The formal model is implemented in simulation software. Various scenarios and experiments are then carried out to test different approaches.

The results are evaluated and compared with the project objectives. Verification and validation ensure that the model and data are correct and that the simulation realistically reflects reality.

The end result is an executable model with reliable simulation results that serves as a basis for informed decisions.

The following graphic shows the typical steps from data acquisition to analysis and validation.

Source: Rabe, M.; Spieckermann, S.; Wenzel, S.: A New Procedure Model for Verification and Validation in Production and Logistics Simulation. In: Mason, S. J.; Hill, R. R.; Mönch, L.; Rose, O.; Jefferson, T.; Fowler, J. W. (eds.): Proceedings of the 2008 Winter Simulation Conference, 2008, p. 1720

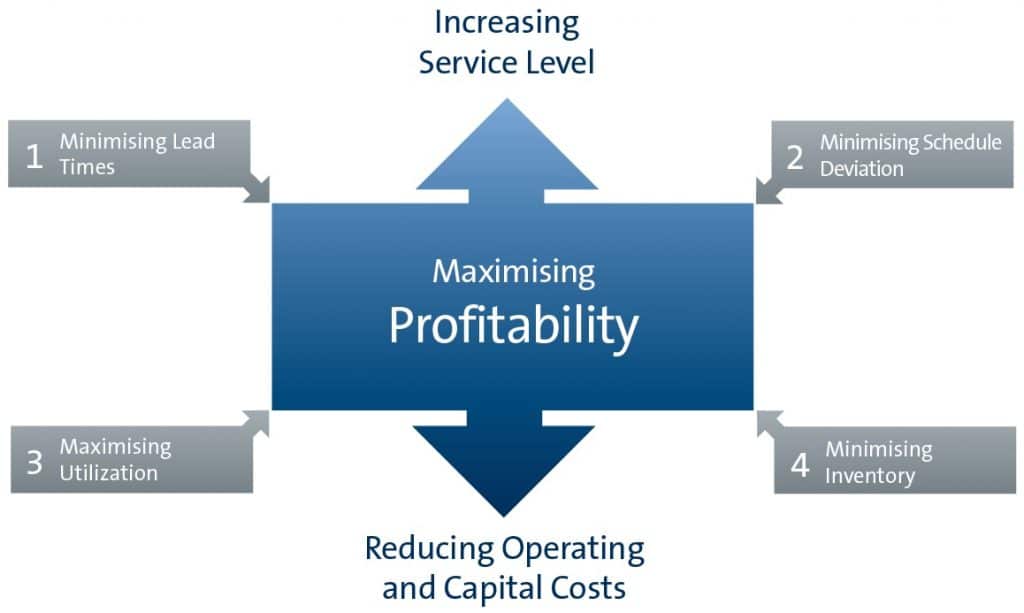

Formulating clear objectives is the first step in any simulation study. The primary focus is always on increasing a company’s profitability. Process simulation increases profitability by increasing throughput and utilisation, shortening lead times, reducing inventories and evaluating layout or control alternatives.

Depending on the issue at hand, a simulation study can have different focal points, for example:

These objectives can be used to influence the key control variables:

This increases the economic efficiency of the system while reducing operating and capital costs – the decisive benefit of systematic process simulation.

Increase of profitability according to VDI 3633 (2010)

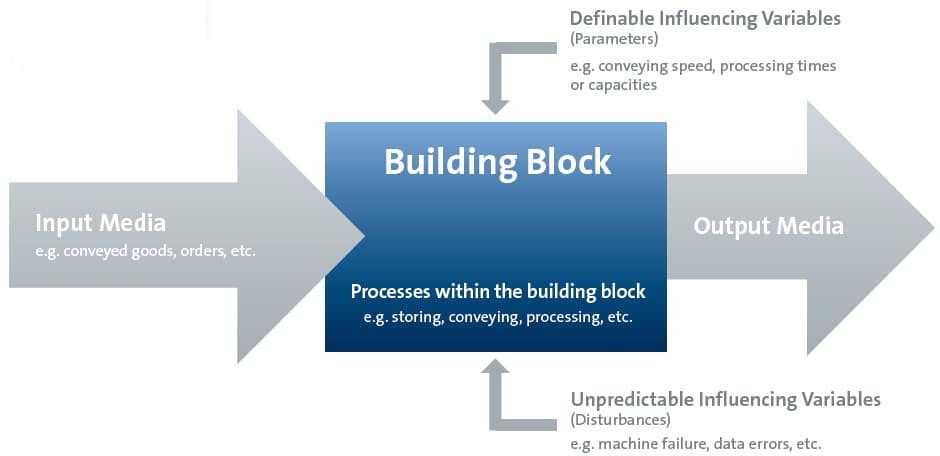

Simulation digitally maps complex systems by creating models from building blocks and connecting them to form a network. This model can be visualised using 2D or 3D animation, enabling a clear understanding of processes and procedures.

Description of the building blocks of a simulation system

The individual building blocks and the processes within the building blocks are linked to form an overall process. This creates a network. With the help of the building blocks and the network, a wide variety of logistics systems can be mapped.

All processes within the network can be visualised using 2D or 3D animation.

Several developments are currently underway to make simulation even more effective:

Process simulation is increasingly being integrated with digital twins, AI and sustainability goals. In the future, simulations will not only help to increase efficiency and optimise layouts, but also to reduce carbon footprints, enable real-time analyses and provide enhanced visualisations.

With the constant expansion of the range of applications, new opportunities are emerging for companies to use simulation in the future to increase profitability and sustainability.

Simulation helps to reduce emissions and energy consumption and make supply chains more resilient. It allows CO₂ footprints, material flows and alternative scenarios to be analysed before they are implemented in reality.

The requirements for supply chains are changing: companies must act sustainably while remaining crisis-proof. Simulation is an effective tool for this.

Simulation is a powerful tool, but it reaches its limits when the model and data are not sufficiently accurate. Missing data, incorrect levels of detail or insufficient consideration of disturbance variables limit its informative value. New trends such as AI, real-time data and uncertainty analyses are helping to increasingly overcome these limitations.

Simulation only delivers reliable results if the model and data quality are correct.

Simulation is a cross-functional task and should be integrated into the organisation in such a way that it is involved in projects at an early stage, has quick access to data and works closely with specialist departments. It is most effective when positioned as a staff unit at plant or management level or in the departments with the greatest need.

Simulation affects many areas of a company – from supply chain and logistics to production and order control. That is why the question of the right organisational anchoring is crucial.

Good organisational embedding ensures that simulation is used systematically rather than selectively, allowing it to fully unfold its effect on profitability, planning reliability and innovation capability.

A digital twin is a virtual replica of a real product, system or process that is continuously supplied with real-time data and reflects its physical state throughout its entire life cycle – from planning and operation to maintenance. In contrast, a traditional simulation is usually static or scenario-based – it uses historical or assumed data to test hypothetical ‘what-if’ scenarios without automatic updating.

A digital twin requires smart sensors and IoT devices, a reliable data infrastructure with open interfaces, edge and cloud computing, and clean, standardised data. Secure integration into existing IT systems and processes is also crucial.

A functional digital twin requires several technical components that work together seamlessly:

Depending on the application and IT environment, various licensing models are available. Here is an overview of the most important ones:

One-time purchase with permanent use. Installation is usually carried out locally in your own network, with updates and support usually provided via maintenance contracts. Ideal for long-term use on a dedicated IT infrastructure.

Temporary use (e.g., annually). Offers flexibility for changing requirements and reduces initial investment.

The license is only charged as long as it is in use or a certain amount of computing power is accessed. As a rule, the customer purchases a certain quota of usage in advance, e.g., in the form of tokens.

The license is “married” locally to a computer or hardware. As a rule, a unique hardware ID is determined and licensed based on the components installed. The most popular and frequently offered are hardware tokens in the form of a USB dongle that must be plugged into the hardware.

The license is assigned to and licensed for a natural person. Identification is usually done via email address. The license can thus be used on different devices.

Multiple users share a certain number of licenses within a company, which are made available via a license server in the local network by installing and licensing a license server. Efficient for larger teams that do not work with the software at the same time.

Installation and operation takes place on your own hardware. This means that no network access is necessary.

Cloud-based model with use via the Internet. No local installation, automatic updates, easy scaling. Particularly interesting for distributed teams or the rapid deployment of digital twins.

Enable the execution of finished models or are specifically designed for temporary projects – a cost-effective alternative to the full version.

The right license depends on the duration of use, number of users, and infrastructure. We would be happy to advise you on which model suits your application scenario.

Of course, these brief explanations cannot replace an intensive discussion on your individual requirements and the possible applications of simulation in your company.

We are happy to answer any further questions you might have. Contact us and we will immediately get in touch with you.

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Turnstile. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from reCAPTCHA. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information