OPTIMISED – Research project for innovative production planning

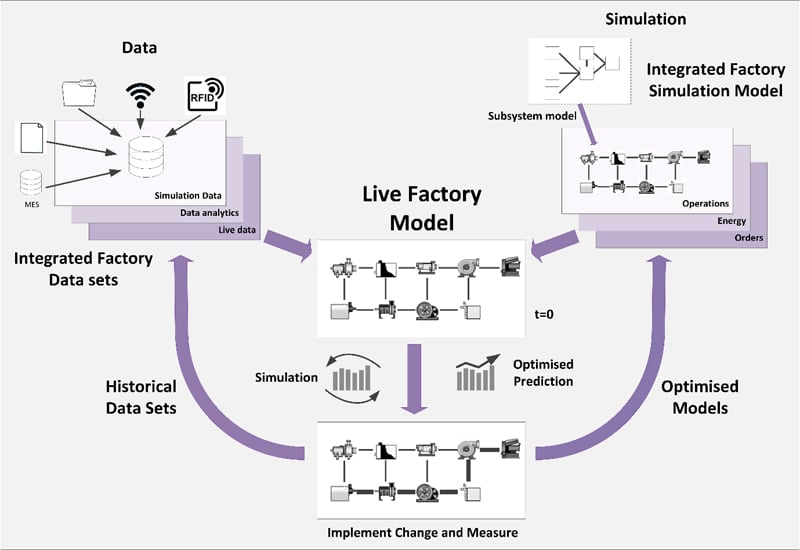

OPTIMISED (“Operational Planning Tool Interfacing Manufacturing Integrated Simulations with Empirical Data”) is an interdisciplinary and international research project, which aims at increasing the Technology Readiness Level (TRL) of different production planning technologies.

OPTIMISED researches new methods and tools for the development of reactive planning systems. Factory modeling and simulation are used, based on empirical data obtained through intelligent sensors and proactive human-machine interfaces.

The OPTIMISED environment will use process modeling, among other tools, to develop a simulation toolbox that supports planning specialists, production engineers, and manufacturing staff throughout the plant lifecycle.

Models built on this toolbox, supported by MES with OPTIMISED technology, are expected to enable improvements in system performance, operational efficiency, plant utilization, real-time station performance monitoring and resource optimization.

The OPTIMISED research partners

In addition to SimPlan AG and Advanced Data Processing GmbH from Germany, the OPTIMISED research partners also include Dassault Systemes BV from the Netherlands, Laing O’Rourke plc, the University of Nottingham, and Smarter Grid Solutions from the United Kingdom, as well as Keonys SAS and Alstom Transport SA from France and Ideko S.COOP and GOIMEK S.COOP from Spain.

Die Beteiligung von drei Endanwendern (Laing, Alstom and Goimek) from three different industries (prefabricated building components, railroad, mechanical engineering) allows a broad evaluation of the developed models and methods.

The OPTIMISED research project is funded by the EU Horizon2020 program.