anyLogistix: a multi-method simulation tool for supply chain optimisation

anyLogistix is a unique software for supply chain and logistics simulation. As the currently only multi-method software for supply chain optimization, network design and analysis, it combines traditional analytical optimisation approaches with the innovative simulation technology developed by AnyLogic.

Analytical optimisation: the supply chain is modelled as a series of formulas and equations. This method will give quick results, but it won’t show the whole story.

Simulation: allows you to consider all of the details and specific traits of your supply chain elements. Not only will you be able to visualize network operations but also trace every process inside.

Every supply chain is unique – capture yours!

With a detailed supply chain simulation model, you can capture the logic and predict the behaviour of your network, even within the four walls of your warehouses and factories. Potential problems that require management action can be predicted and identified.

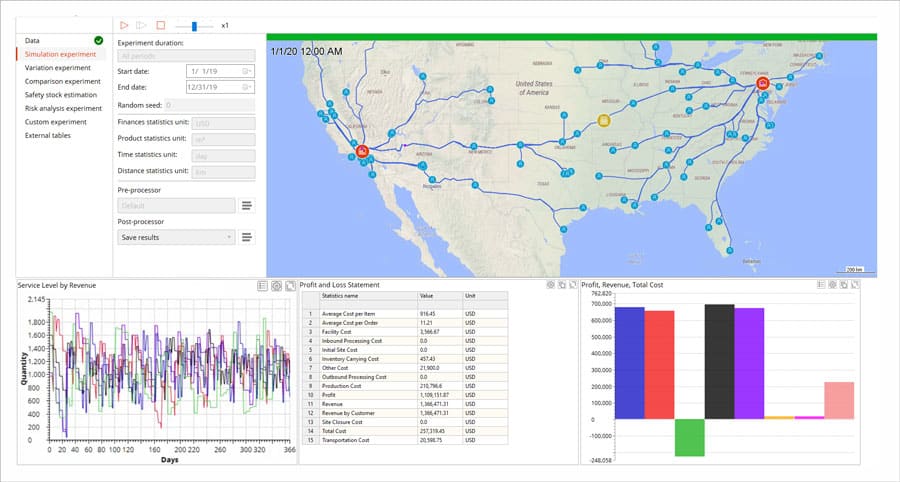

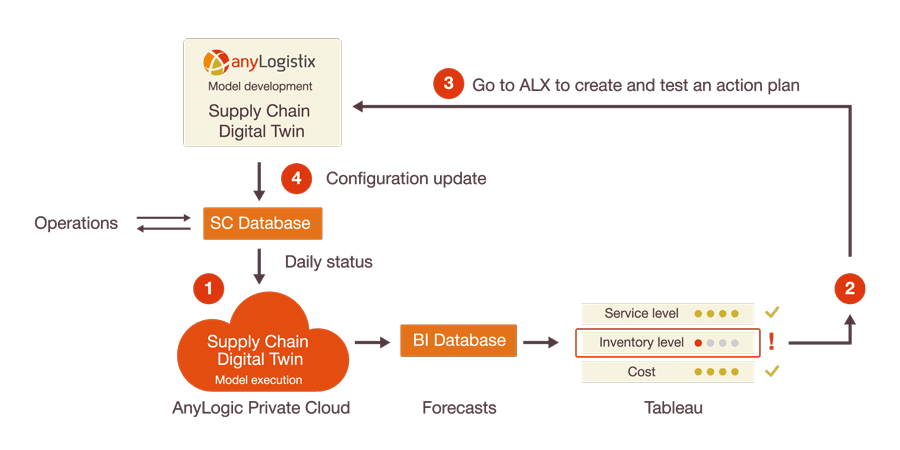

Develop and test action plans. Use any Logistix experiment, such as optimisation, risk analysis, safety stock estimation, and transportation optimisation, to create action plans. Then test them, get forecasts, and examine their performance.

Automatically collect data from your supply chain and configure the objects, processes, and entities of your supply chain model.

Receive alerts and take action with notifications and triggers. For example, if service levels drop or stock levels are running low, you can alert users and execute defined actions to avoid critical situations.

anyLogistix integrates with your existing technology, enabling you to process, manipulate and present your supply chain data as you need it.

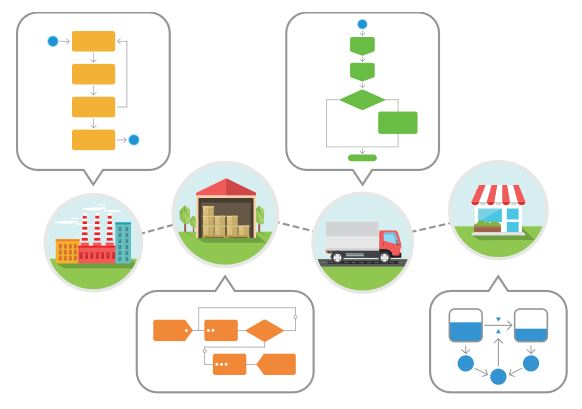

Design and simulate in one step

anyLogistix combines network optimisation analytical tools with a unique dynamic simulation engine. By using these techniques together, it delivers more accurate and transparent decision support models that enable more efficient analysis.

Define the network structure with the optimisation, then analyse all the specifics with the simulation – examine every single aspect of your supply chain.

anyLogistix simulation is based on AnyLogic®, the industry-leading simulation software tool, combined with the renowned optimisation capabilities of IBM ILOG CPLEX®.

Supply chain modelling

Every supply chain is unique and has its own specific characteristics. Dynamic simulation allows you to capture the characteristics of your network at any level of detail. anyLogistix standard policies, behaviours and location characteristics can be customised using AnyLogic simulation software to represent the unique characteristics of your supply chain. You can describe the constraints and rules of supply chain operations as they exist for accurate, non-averaged results.

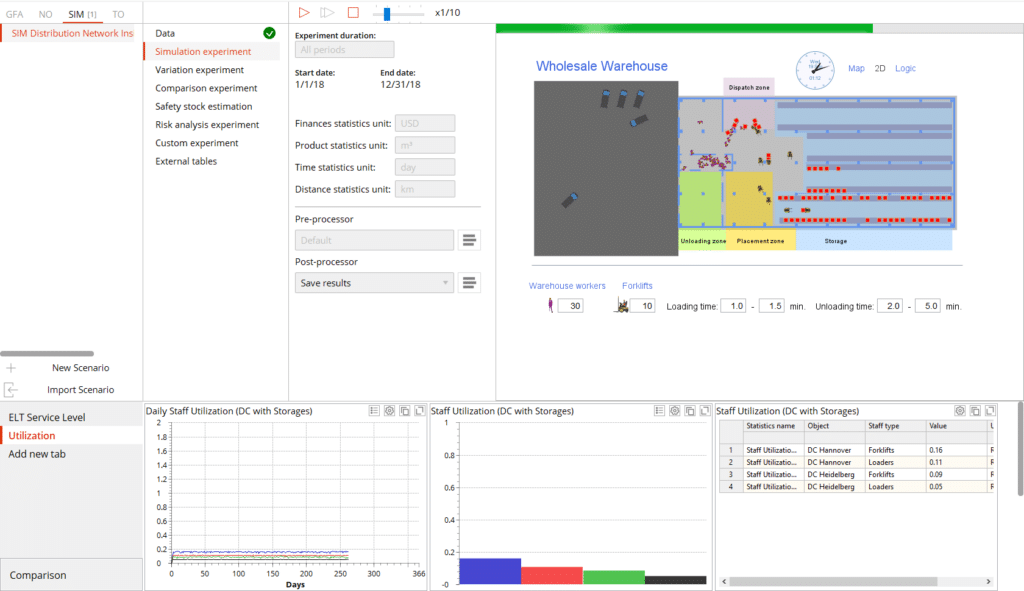

Simulation within four walls

With ALX, you don’t have to stop your analysis at the network level. Go deeper with detailed modelling of site operations within four walls, such as:

- Warehouses and DCs down to the level of a pallet and forklift

- Factories, including conveyors and operations

- Retail stores

- Customer locations

Uncertainty and risk analysis

anyLogistix can examine how randomness within a supply chain can affect the system: ALX’s built-in simulation models account for probabilities in operation times and values.

Simulations allow you to analyse the risks associated with real-life uncertainties, including lead times, demand fluctuations, resource availability and other varying parameters.

Visualisation and model transparency

In addition to the realistic calculations, the simulation provides live animation, allowing you to see the operations in the supply chain in action. This transparency makes it possible to examine network dynamics as a model runs and to validate a system’s representation.

With animation, your model is not a black box. Animation makes it possible to visualise scenarios so you can see how the model works, lending credibility to your results.

anyLogistix allows you to explore how a model arrives at its results. By changing model parameters during execution, you can uncover cause-and-effect dependencies – for example, how a change in warehousing policy affects bullwhip.

Measure everything

With dynamic simulation, you can measure every key parameter in your supply chain, including how the values change over time. You can use a whole range of pre-configured statistics or create your own.

Case study: Optimising the supply chain – scalable solutions for the building materials industry

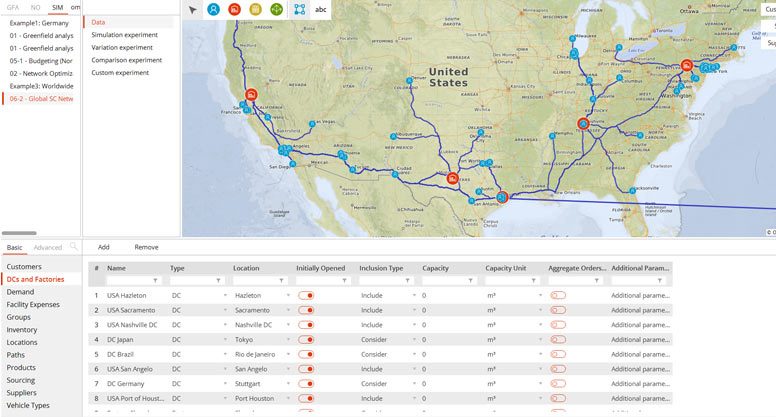

SimPlan helped a large German building materials manufacturer with 24 plants and 6,000 products to optimise its supply chain.

The aim was to develop a scalable and cost-efficient network for the predicted growth by 2030.

Challenges included the decision between a centralised or decentralised structure, the optimal choice of location for production and warehousing, and the evaluation of effects on delivery times, transport costs and inventories.

SimPlan used the anyLogistix software to analyse and optimise the network.